Powder and Liquid Sand Grinding Machine Pigment Horizontal Beads Mill

Basic Info

| Trademark | JRX |

| Origin | China |

| Production Capacity | 1000 Set/Sets Per Year |

Product Description

Sand millProduct feature

JRX-G series horizontal closed sand mill, compared with ball mill, roller mill, colloid mill, and other dispersing equipment, has the advantages of high production efficiency, uniform particle size distribution, strong continuity of production, low cost, and so on. This series of sand mills can be customized explosion-proof type, widely used in coating, dye, ink, medicine, magnetic recording materials, ferrite, photographic film, strontium carbonate, and other industrial sectors of efficient grinding and dispersion. According to the effective volume of the cylinder 1.5-250l, it can be divided into 10 specifications including 1.5l, 5L, 15L, 20L, 30L, 50L, 60L, 100L, 150L and 250L. JRX-G series grinders are designed to type A (front-end discharge) and type B (back-end discharge).

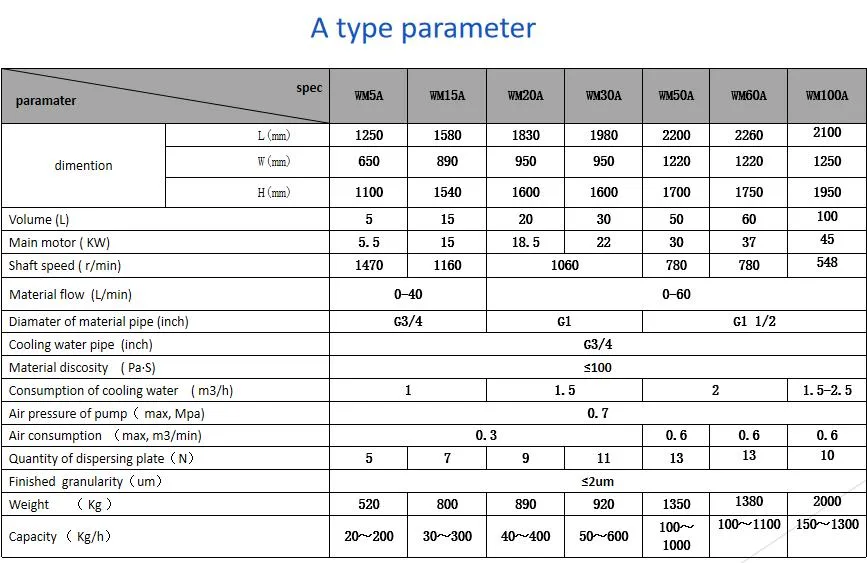

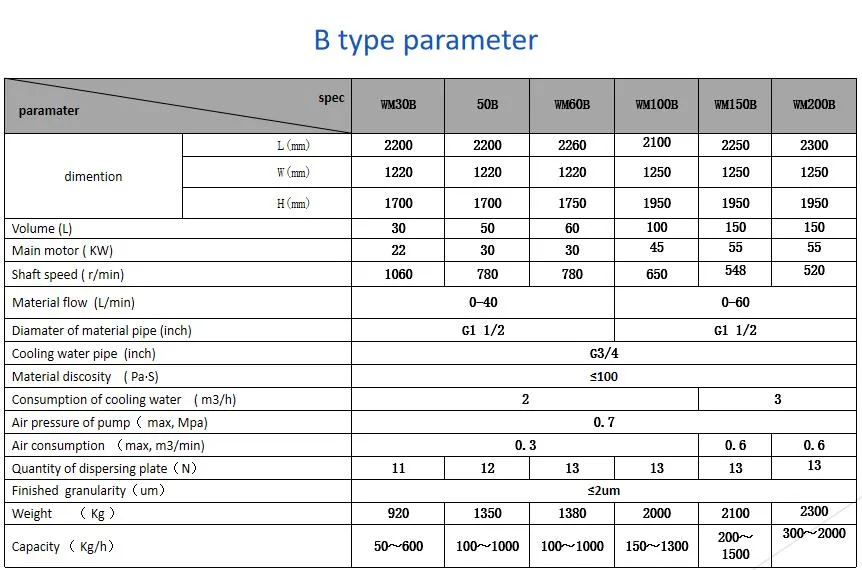

Technical Parameters

A type(front-end discharge)

The overall structure JRX-G series sand grinder consists of a mechanical seal device, disperse shaft subassembly, grinding cylinder body, pressure controller (optional) and temperature meter, main motor, transmission system, feed pump, body, and electrical system.The working principle Pump transfers the mixed materials of solid/liquid after the pre-wetting process to the cylinder body, and the materials are stirred by a high-speed rotating dispersion plate together with grinding media in the cylinder body, making strong shear of the material of solid particles between the grinding media, to achieve the purpose of grinding fine particles and dispersing agglomeration particles. After grinding, the material is discharged through a dynamic separator or static separator.

The fuselage is a steel welding body that fixes and supports the main machine, the feeding pump, the cylinder body, and the electric box. It is stable and reliable and has a compact structure. The bottom of the fuselage is equipped with four adjustable shock pads to ensure the level of the whole machine.

Overseas sales

Company Profile

We are Qingdao JRX M&T

Which company is mainly engaged in paper coating machines, paper machines,s and related technology? After more than ten years of effort, in addition to the machine itself, we have our chemists, more willing to provide customers with chemistry, formulation, technology, and other advice. Then our formulations will match our machines and get the best quality paper for them. At present, the company has become one of the famous paper coater manufacturers in China, coater and technology has been exported to Egypt, Mexico, Australia, India, and other countries.

FAQ

1. Is there a person who replies to me?

Our person is 24 hours online. If no reply, please leave your message via e-mail and chat tools, and we will reply to you as soon as possible.

2. Why did we choose your company, what could you do for me?

We have been established for more than 10 years, we have stable production experiences.

We use the best steel to guarantee the products' quality.

We will always give you heart-to-heart service.

We always speak with facts and quality.

3. Could your engineers teach and train our workers and stay in our factory for a long time?

Yes, we have a very large installation team, they can train and teach your worker to operate the paper machine, but you should pay them a salary.

4. How can I know your machine works well?

Before delivery, we will test the machine's work condition for you.