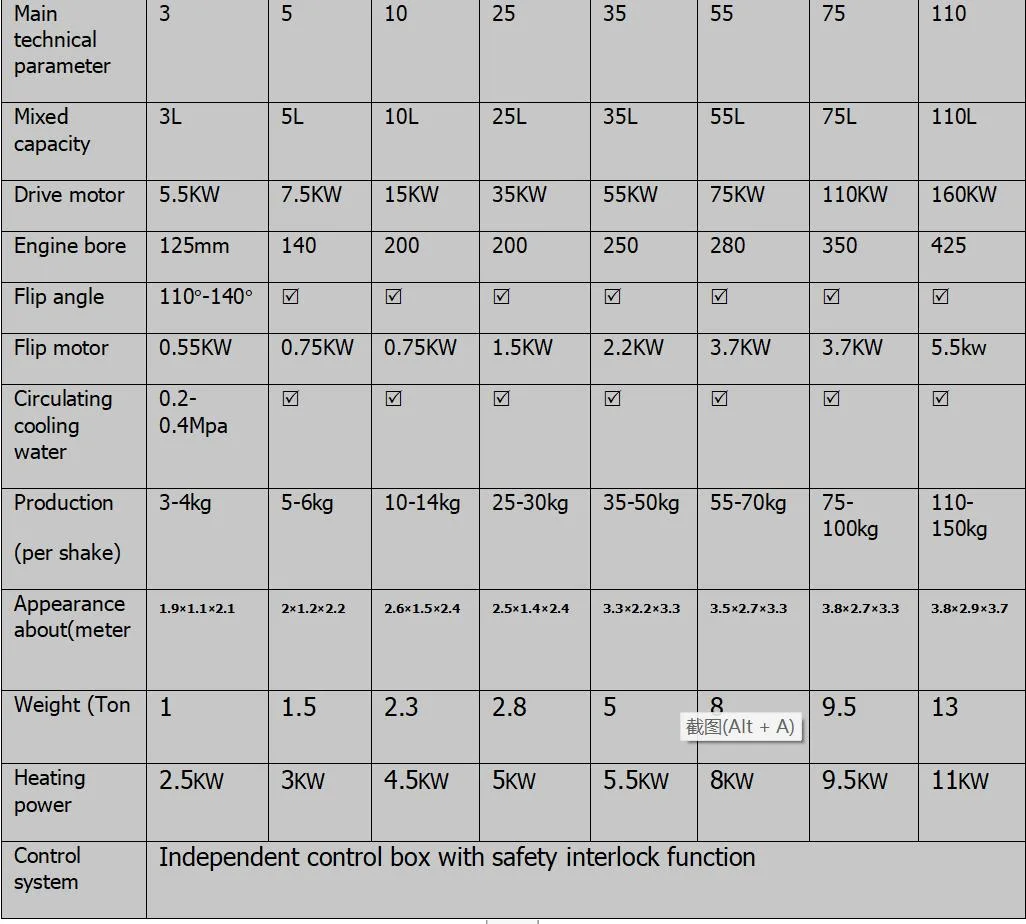

Used 110 Litre Industrial Rubber Dispersion Kneader Chemical Mixing Machine

Banbury Mixer, Kneader, Banbury KneaderUsed 110 litre Industrial Rubber Dispersion Kneader Chemical Mixing Machine Param

Basic Info

| Model NO. | YZM-110L |

| Transport Package | Wood Packaging |

| Specification | 3700X2370X3200mm |

| Trademark | YZ |

| Origin | China |

| HS Code | 8477800000 |

| Production Capacity | 1000unit Per Year |

Product Description

Banbury Mixer, Kneader, Banbury KneaderUsed 110 litre Industrial Rubber Dispersion Kneader Chemical Mixing MachineParamater

Feature:

* The spiral angle and the working length of the wing of the rotors are designed intelligently and reasonably, which can make the materials obtaining an optimal kneading effect. The wing ridge and the end surface of rotor are bead welded with the abrasion resistant hard alloy and the faying surface of mixing chamber, rotor and upper ram which directly touching with the materials are all polished after being ground and plated with hard chromium

* The mixing chamber consists of W-shape body welded with high quality steel plates and two pieces of side plates. The chamber, rotors and piston ram are all jacketed structure for the ingoing of steam, oil and water for heating and cooling to suit the various requirement for the process of mixing and plastication.

* Hard toothed surface gear reducer for higher working efficiency, lower noise, wearing resistance; Well-known brand motor with 20 years guarantee.

* PLC control for banbury mixer.

*This Dispersion Kneader Machin consists of seat, Frame, Rubber, Driving device, Lubricator and cooler, range adjusting device of roller. Safety brake. Motor and reducer, etc.

*This Dispersion Kneader is suitable for processing single or mixing numerous raw materials, including natural, rubber, synthetic rubber, plastic and more

* The internal Mixer is widely used in natural rubber refining, raw rubber and compound mixing. Rubber beating mixing and rubber tab letting

Frequently Asked Question1.

Q: Are you a manufacture or trading company? A: We are a direct manufacture in this field for more than 18 years.2.

Q: Where is your factory?and How can I get there?

A: Our address is No.11,South Area GangKou Road,LuoChong Village,XinHe Community,Wan Jiang,DongGuan,GuangDong Province, China. When you arrived GuangZhou or ShenZhen airport ,we are happy to pick you up.3.

Q: Can you custom made and do you supply sample? A: Sure ,since we are manufacturer ,so we can custom made the machine as per your needs. We can custom made or provide us your our stock sample. 4.

Q: How does your manufacture deal with quality control? A: From the beginning of production to delivery time, every step goes through ISO9001 quality management system and ERP scientific management system.5.

Q: Do you accept OEM or ODM such as customer's logo and color and so on? A: Yes. We are pleasure to supply OEM or ODM service for you. 6.

Q: What serve do you provide? A: 1. Oversea installation guide. 2. Oversea test running 3. Oversea worker training 4. Technical support 5. supply of spare parts 6. Technical operation support 7. Formula and processing support7.

Q:Could you please tell us about your installation and Commission serve?

A: (1) Strict commissioning will be made before shipment to ensure the machine would work before when you get them (2) Overseas Commissioning and charges one or two technicians will be sent to the buyer to guide the installation and commissioning of the equipment if the customer requests. Customers need to pay the charge of our technicians. (1) Round-trip Airplane Ticket (2) Charges of transportation, accommodation and communication (3) The allowance for the technicians is USD 80 per day for one person. (4) An interpreter is needed. 8.

Q: Can you please provide us spare parts?

A: Sure ,that is not problem. We would provide you spare parts needed for one year. 9.

Q: What is your lead time? A: We would deliver the goods to you within 50 days on receipt of your deposit. 10.

Q: What are your terms of payment? A: We accept T/T, Western Union and others. 11.

Q: What is your regular packaging? A: Equipments packed with packaging film and foam inside, outside packed with exempted from inspection of wooden packaging.12.

Q: How is about the after-sales service? A: Our equipments have one year guarantee and life-long maintenance. We also have a strong and technical team for after-sales service.

Send to us