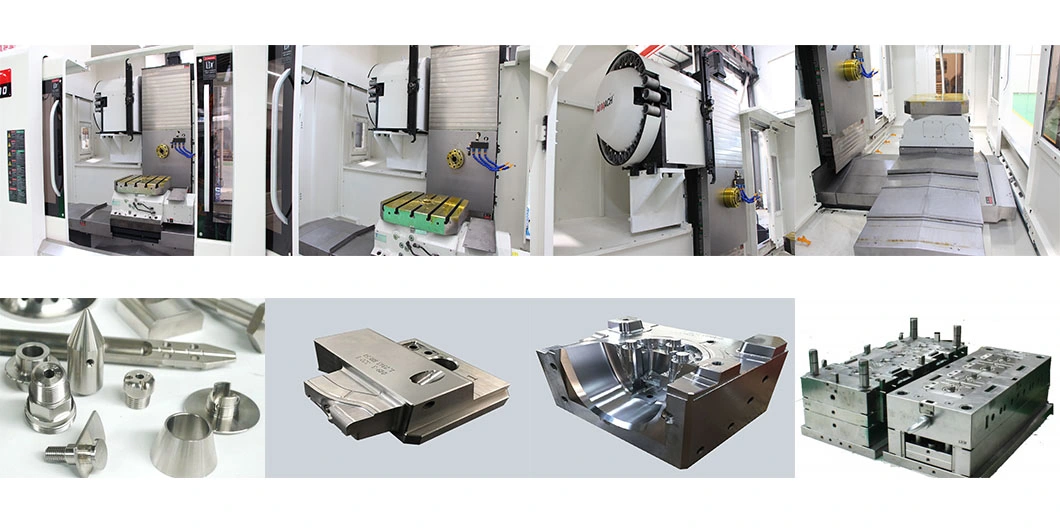

Bymc Hmc500 CNC Machining Center Heavy-Duty Horizontal Machining Center for Machining Car Molds

Basic Info

| Model NO. | HMC500 |

| Process Usage | Metal-Cutting CNC Machine Tools, CNC Non-Conventional Machine Tools, Metal-Forming CNC Machine Tools |

| Movement Method | Contour Control |

| Control Method | Semi-Closed Loop Control |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.02~0.03(mm) |

| Performance Classification | High-End CNC Machine Tools |

| Certification | CE, ISO 9001 |

| Condition | New |

| X/Y/Z-Travel | 1000*500*500 |

| Table Size | 500*500/1000*500 |

| Distance From Spindle Centerline to Work | 50-750 |

| Distance From Spindle End Face to Work T | 20-720 |

| Workbench Maximum Load | 800 |

| Feed Movement Speed X, Y, Z | 1-10 |

| Positioning Accuracy (JIS Standard) | ±0.008/300 |

| Repeated Positioning Accuracy (JIS Stand | ±0.005 |

| Approximate Dimensions | 3100*2550*2900 |

| Machine Weight Approx. | 7800 |

| Transport Package | Wooden Case |

| Specification | 3100*2550*2900 |

| Trademark | BYMC |

| Origin | China |

| HS Code | 8457102000 |

Product Description

1 Overall layout of the machine tool

HMC500 horizontal machining center adopts a vertical frame layout, the column is fixed on the bed, the headstock moves up and down along the column (Z direction), the sliding seat moves longitudinally along the bed (Y direction), and the worktable moves laterally along the sliding seat (X direction). to the structure.

The bed, worktable, sliding seat, column, spindle box and other large parts are made of high-strength cast iron material, and the shape is resin sand process, and two aging treatments are used to eliminate stress. These large parts are optimized by SW and Ansys to improve the rigidity and stability of the large parts and the whole machine, and effectively suppress the deformation and vibration of the machine tool caused by cutting force.

2 Drag system

The XYZ axis adopts linear guideway, 45 roller structure, the overall operation noise of the machine tool is low, the friction force is small, the sensitivity is high, the high-speed vibration is small, the low-speed crawling is not, the positioning accuracy is high, the servo drive performance is excellent, and the accuracy and precision of the machine tool are improved. sex.

X, Y, Z axis servo motors are directly connected with high-precision ball screws through elastic couplings, reducing intermediate links, realizing gap-free transmission, flexible feeding, accurate positioning, and high transmission precision.

The Y-axis has good stability under heavy load and strong cutting.

The Z-axis servo motor has an automatic brake function. In the event of a power failure, the automatic brake can hold the motor shaft tightly so that it cannot rotate.

The role of safety protection.

3 spindle groups

The spindle group is produced by Taiwan professional manufacturers, with high precision and high rigidity. The bearing adopts P4 grade spindle special bearing. After the whole set of spindles is assembled under constant temperature conditions, they all pass the dynamic balance correction and running-in test, which improves the service life and reliability of the whole set of spindles.

The spindle can realize stepless speed regulation within its speed range, and the spindle is controlled by the built-in encoder of the motor, which can realize the function of spindle orientation and rigid tapping.

4 tool magazine

It adopts Okada or Desu 24 disc manipulator tool magazines, which are installed on the side of the column. It has the characteristics of fast changing speed (7 seconds), accurate tool changing, high efficiency and long service life.

5 Cutting cooling system.

Equipped with a large-flow cooling pump and a large-capacity water tank to fully ensure circulating cooling, cooling pump power: 0.45Kw, pressure: 1.2bar.

The end face of the headstock is equipped with cooling nozzles, which can be either water-cooled or air-cooled, and can be switched at will, and the cooling process can be controlled by M code or control panel.

Equipped with cleaning air gun and water gun to clean the machine tool.

6 Pneumatic system

The pneumatic triplet can filter impurities and moisture in the air source, preventing impure gas from damaging and corroding machine tool components. The solenoid valve group is controlled by the PLC program to ensure that the spindle loosening, the spindle center blowing, the spindle clamping, and the spindle air cooling can be completed quickly and accurately.

7 Machine tool protection

The machine tool adopts a protective room that meets the safety standards, which not only prevents the splash of coolant, but also ensures safe operation and a pleasant appearance. Each guide rail of the machine tool has a protective cover to prevent chips and coolant from entering the inside of the machine tool, and protect the guide rail and ball screw from wear and corrosion.

8 Lubrication system

The guide rail and ball screw pair are all lubricated by centralized and automatic thin oil. Each node is equipped with a quantitative oil separator, which regularly and quantitatively injects oil into each lubricated part to ensure uniform lubrication of each sliding surface, effectively reducing frictional resistance and improving motion. The precision ensures the service life of the ball screw pair and the guide rail.

9 Chip removal system (optional)

The iron filings generated during the machining process fall directly onto the guard room, and the protective internal inclined surface structure makes the iron filings slide down smoothly into the chip flute, and then conveys the iron filings to the chip collecting trolley through the screw chip conveyor, which is simple and practical. Economical.

| Main technical parameters | Unit | HMC500-A |

| Travel parameters | ||

| Left and right stroke (X axis) | mm | 1000 |

| Front and rear travel (Z axis) | mm | 500 |

| Up and down stroke (Y axis) | mm | 500 |

| Distance from spindle centerline to worktable | mm | 50-750 |

| Distance from spindle end face to work table | mm | 20-720 |

| The maximum rotation of the workpiece on the work surface | / | / |

| Workbench parameters | ||

| Table size | mm | 500*500 |

| table indexing | / | / |

| Workbench maximum load | kg | 800 |

| feed parameters | ||

| X-axis rapid movement speed | m/min | 24 |

| Y-axis rapid traverse speed | m/min | 24 |

| Z axis rapid traverse speed | m/min | 24 |

| Feed movement speed X, Y, Z | m/min | 1-10 |

| Spindle parameters | ||

| Spindle connection | ||

| Spindle taper | BT50 | |

| Spindle speed range | Rpm | 8000 |

| Spindle motor power | kw | 15 |

| Tool magazine parameters | ||

| Tool magazine capacity | qty | 24 |

| Maximum tool size | Φ120/300mm/Φ78 | |

| Maximum tool weight | kg | 8 |

| Precision | ||

| Positioning accuracy (JIS standard) | mm | ±0.008/300 |

| Repeated positioning accuracy (JIS standard) | mm | ±0.005 |

| Appearance and Weight | ||

| Approximate dimensions | mm | 3100*2550*2900 |

| Machine weight approx. | kg | 7800 |

Q1: How is the warranty?

A1: Warranty time is 13 months after the BL date.

Q2:Can we visit your factory before ordering?

A2:Sure.All new and old friends are welcome to visit us at our factory. Besides, we can pick up you at the station or airport if needed. We will be very honored to help with tickets and accommodation booking.

Q3:Do you have a stock?

A3:Sorry, most of our machines don't have stock, we always produce according to order. However, if during fairs months, maybe have few samples back from fairs.

Q4:What's the MOQ?

A4:One set only.

Q5:How about your quality?

A5:We have approved the ISO9001:2008 Quality management system.ISO14001 Environmental management system, OHSAS18001 International occupational health and safety management system, and Social Accountability 8000(SA8000). Most products have been approved by the European and American safety standards, including CE, GS, EMS&UL,90% of our products are exported to more than 60 countries and regions around the world, especially to Europe and the American market, and always win high reputation. So you can rest assured of our quality products and our best services.

Q6:Do you have professional engineers?

A6:Yes.we have professional engineers and designers. We can provide OEM services.

Q7:Can you provide customized machines?

A7:Yes, we can design and manufacture according to your specific requirements.