Horizontal Bead Mill for Ink/Paint/Pigment Production Wet Grinding Machine

Basic Info

| Model NO. | EDW |

| Certification | CE, ISO, CCC |

| Application Area | Pharmaceutical |

| Layout Type | Horizontal |

| Additional Capabilities | Milling, Drying, Granulating, Coating |

| Operating type | Continuous Operating |

| Condition | New |

| Function | Wet Grinding/ Milling |

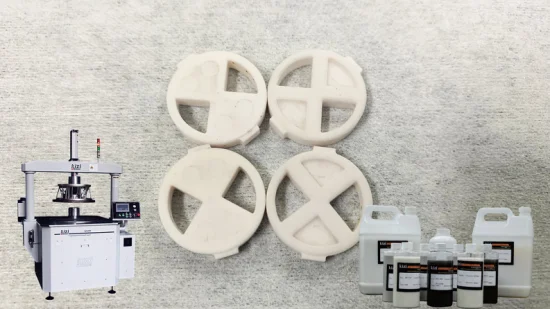

| Grinding Medium | Zirconia Beads |

| Applicable Industry | Coating, Paint, Ink, Pigment, Latex |

| Materials | Hard Alloy Steel, Ceramic Optional |

| Usage | Industrial Production |

| Product Type | Paint |

| Feeding Pump | Pneumatic Pump or Gear Pump |

| Transport Package | Standard Export Wooden Case |

| Specification | bead mill |

| Trademark | ELE |

| Origin | Shanghai, China |

| HS Code | 8479820090 |

| Production Capacity | 100 Sets/Month |

Product Description

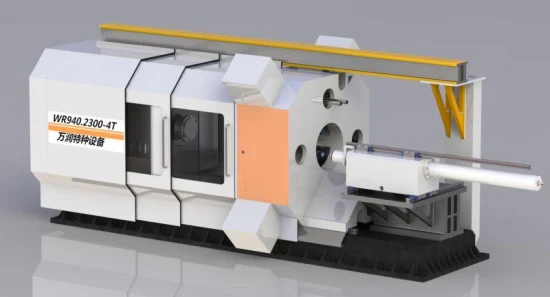

Horizontal Bead Mill (EDW)

Introduction:

- ELE horizontal pearl mill cooperates with Switzerland technology, with advanced structure, high efficiency, nanometer and micron final fineness. It is widely used in the industry production of paint, color paste, printing ink, papermaking, adhesive, drugs, chemical industry etc.

- It adopts specially wear-resisting materials, prolonging service life, and well adopted to different viscosity of materials.

Middle, Low, High viscosity raw material, suitable for super fineness required Paints and printing inks, high quality car paint, pigments and dyes, ...A high abrasion nanoscale bead mill.

Features:

1. High abrasive resistance: Materials (zirconia, tungsten carbide, hard alloy etc. ) guarantee working life.2. Dynamic fence booms: Discharge solve problems of slow discharge and grinding medium getting stuck.3. German BURGMANN double mechanical end face seal, which can bear more than 10bar pressure.4. Corrugated cooling system increase cooling area and improve cooling efficiency.5. Grinding beads small to 0.2mm guarantee superfine grinding/milling.6. Meet demands of continuous production&different viscosity& fineness.7. Inner & outer double pins improve high wet grinding/milling efficiency.8. Ex-proof (optional) & fault alarming.

Application:

Coating: Water-based coating, Solvent-based coating, Decorative Coating, Latex paint;Paint: Car Paint, Finish paint, Wood paint, Industrial paint;Ink: Gravure Printing ink, Flexographic ink, Offset printing ink, Silk screen ink, UV light solid ink, Digital inkjet ink etc;Pigment: Dye, Color painted pigment, Pen liquid,Watercolor;Electronic Materials: Battery diaphragm alumina, Lithium iron phosphate, Ceramic slurry, Flame retardant;Food Industry: Chocolate Syrup, Paste etc;Pesticide: Pesticide suspension, EC, EW, ME;Daily Chemical Industry: Cosmetics, Liquid soap, Shower gel, Liquid detergent etc;Biological Medicine: Algae cell fragmentation, Micro-biological functional materials;Nano Materials: metal oxide, Magnetic Materials, Paper industry, Optoelectronic industry.

Technical Parameters

| Model | Volume Of Grinding Chamber(L) | Power(KW) | Rotation Speed (rpm) | Capacity(L/H) | Dimensions(mm) | Weight(KG) |

| EDW-5 | 5 | 11 | 1500 | 200 | 1300*1050*450 | 650 |

| EDW-10 | 10 | 15 | 1500 | 300 | 1600*1450*650 | 980 |

| EDW-15 | 15 | 30 | 1500 | 500 | 1600*1450*650 | 1200 |

| EDW-20 | 20 | 30 | 1260 | 800 | 1600*1450*650 | 1350 |

| EDW-30 | 30 | 55 | 1260 | 1200 | 1650*1550*750 | 2100 |

| EDW-50 | 50 | 75 | 980 | 2000 | 1900*1850*850 | 2300 |

ELE Services

Pre-Sale Service: ELE's skillful and experienced experts could provide you with professional technical consulting and designed proposal. We are owning modern Nano Laboratory and could help clients do test running before model selection and pirchasing, generate lab report and guide your actual production.

On-Sale Service:With upgraded grinding technology, ELE factory will manufacture good quality machinery and equipment to meet different production fields for customers.

After-sale Service: ELE engineers will be sandby for 24 hrs to provide you with prompt solution. We could send technicians to your factory to help you install the machine, train your workers to operate and help with the debugging.

All wearing parts of ELE machinery is available at any time you need. Our engineer will provide you with spare parts scheme before sending the equipment to help you know when it is needed to change the parts, thus avoiding any delay of yous productions.

Why ELE

Shanghai ELE Mechanical and Electrical Equipment is professional manufacturer of wet processing chemical machinery. Owning 18 years experiences in dispersing and wet grinding field, ELE is your best choice for disperser, lab use sand/bead mill and inustrial sand/bead mill. With cooperation with university , experts and exprienced engineers, ELE has been concentrated in technique of wet grinding machine since 2000. Now ELE wet grinding mills are applied in more than 100 countries, serving for factory production of paint, ink, dye, magnetic material, paste, agriculture chemicals, adhesion, cosmetics, ceramic. With own modern Nano Laboratory and manufacturing factory, ELE could provide clients with the most suitable solution for complete wet gridning production mills. We are expecting cooperation with you!

More about ELE

Delivery & Package