Customized Heavy Duty Aluminum CNC Automatic Cutting Machine

Product Description Product Name: Customized Heavy Duty Aluminum CNC Automatic Cutting MachinePower Supply: 380V/50Hz or

Basic Info

| Model NO. | DS-A800 |

| Horizontal Band Sawing Machine Type | Aluminum Profile Cutting Machine Saw |

| Saw Feed Direction | Horizontal |

| Track | Linear |

| Controlling Mode | CNC |

| Automatic Grade | Automatic |

| Precision | High Precision |

| Certification | ISO 9001 |

| Condition | New |

| Product Name | Aluminum CNC Automatic Cutting Machine |

| Model | Ds-A800 |

| Usage | Large Aluminium Motor Housings, Heavy Aluminium |

| Working Pressure | 0.6-0.8MPa |

| Cutting Height | 280mm |

| Cutting Width | 460mm |

| Main Spindle Precision | 0.01mm |

| Cutting Flatness | 0.1mm |

| Cutting Verticality | 0.1mm |

| Power Supply | 380V/50Hz or Customized |

| Transport Package | Wooden Case or Customized Required |

| Specification | 2600*2050*1760mm |

| Trademark | DS |

| Origin | China |

| HS Code | 8461909000 |

| Production Capacity | 3000 Pieces/Year |

Product Description

Product Name: Customized Heavy Duty Aluminum CNC Automatic Cutting MachinePower Supply: 380V/50Hz or Customized Cutting Height: 280mmCutting width: 460mmCutting flatness: 0.1mmCutting verticality: 0.1mm

Spindle Presicion: within 0.01mm

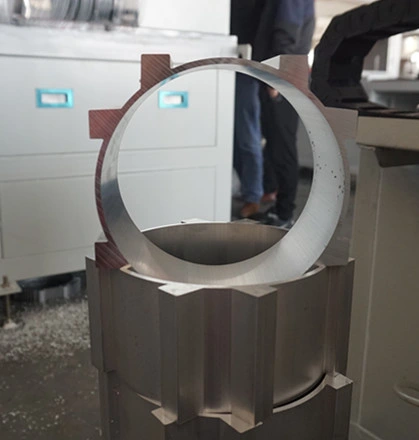

Cutting Materials:Large aluminium motor housings, heavy duty aluminium

Main Features

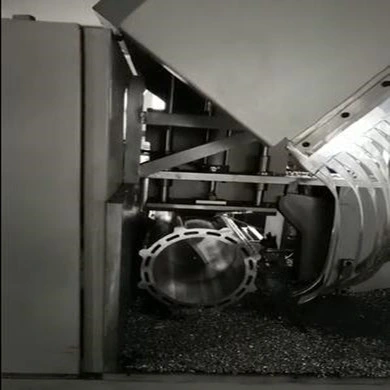

1. Workpiece cutting accuracy is steadily controlled to within ±0.1mm and spindle accuracy to within 0.01mm. 2. The frame is made of structural steel welded and then precision machined to provide a high degree of rigidity and strength. Power is transmitted through a ball screw linear module with stable and reliable performance, high working accuracy, easy operation, etc. 3. The cutting saw blade is made of our own brand (Fujire) carbide inserted tooth saw blade, with high cutting line speed, smooth processing surface and high tool durability. 4.The sawing is done with horizontal feed, using damping cylinder sets of technology to ensure uniform cutting forward speed, dimensional stability and high roughness of the cutting surface.5. The infeed end of the machine is equipped with a pallet, which is fixed to the frame, and the bottom adjusting foot can be fixed to the ground with expansion screws after adjusting the height to a suitable position to ensure that the heavy products are not shaken when conveying.6. The rollers are positioned with polyurethane covered rollers and side covered guide rollers, making feeding easier and more fluid, positioning relatively easy and effectively protecting the workpiece from scratches.7. The machine is equipped with a movable feeding platform (1200*600*830) at the discharge end, the table surface is made of bakelite, smooth and durable to protect the workpiece.8. With a micro-lubrication device and special cutting oil for aluminium alloys to improve the service life of the saw blade and to avoid electrical leakage and electric shock.

Cutting Materials

Specification

| Power Supply | 380V/50Hz or Customized | Model | DS-A800 |

| Motor RPM | 2000r/min | Feeding Precision | ±0.2mm |

| Power | 13KW | Cutting Height | 280mm |

| Working Pressure | 0.6-0.8MPa | Cutting Width | 460mm |

| Spindle Diameter | 40mm | Saw Blade | 800*40*6.5*120T |

| Cooling Device | Micro-lubrication Device | Sawing Direction | Front and back feeding |

| Driving Force | Hydraulic | Automatic Feed Length | 8-1200mm |

| Spindle Precision | 0.01mm | Dimension (L*W*H) | 2680*2050*1760mm |

| Feeding Speed | 0-3m/min | Weight | 1700kg |

Machine details

Why Us1. After nearly two decades of hard work and precipitation, DS Machinery has obtained more than 30 inventions, utility models and appearance patents and a number of software copyrights.2. During the period, it obtained ISO9001: 2015 quality system certification, and at the same time obtained the honors of high-tech enterprises, private technology enterprises in Jiangsu Province, and Suzhou City for abiding by contracts and keeping promises,issued by the government.

3. DS owns 3,500 square meters of workshops, and has established two R&D centers in Huzhou, Zhejiang and Kunshan, Jiangsu, and three service bases in Jiangsu, Zhejiang, and Guangdong.

4. The products are exported to Southeast Asia, the Middle East, Europe, Africa and other places, and more than 3,800 customers have been served worldwide.

Customers

Package

FAQ

Q: Are you manufacturer or trading company?

A: We are a professional manufacturer dedicated to the research and producing of high quality aluminum cutting machines and saw blades for 20 years

Q: Can I have your quotation?

A: First, please offer us the information of your cutting material and its size,without these parameter, we are not able to recommend you the suitable machine

Q: Do you have overseas service? How to provide after-sales service?

A: We normally help our customers to solve the problems through phone, Email, skype, internet video. Very high efficiency

Q: How long is the equipment warranty?

A: We offer one year guaranteen, within one year, if component of the machine broken, we freely offer the component, but the delivery fee should be paide by client

Q: What is the voltage and Hertz in your country?

A: In China,the Voltage is 380V(3 Phase), the Hertz is 50Hz, we can change the voltage and Hertz according to your requirment

Q: What is the delivery lead-time?

A: Aluminum cutting machine: Normally 5-30 days upon receipt of your orders and its deposit. Saw blade: 5-30 days(depending on availability of saw blade stock or material stock) upon receipt of your order and deposit

Q: What is your payment terms?

A: We accept L/C, T/T, D/P, Western Union and PayPal. As T/T, 30% deposit, 70% of balancepaid before shipment

Q: Can you customize for us?

A: Yes

Q: Can you OEM/ODM for us?

A: YesQ:Can I get a discount?

A:Yes, for the yearly order quantity of more than 5 sets, please contact us to get the best price

Q:Do you inspect the finished products?

A:Yes, each step of production and finished products will be coming out inspection by the QC department before shipping

Q: Do you provide equipment operation training? Do you have the operation instruction book in English?

A: Currently we can do on-line technical operation training for customer's staff. Yes, we have English version operation instruction book for each cutting machine.

Send to us