High Speed Heavy Duty CNC Milling and Drilling Machine for Flange

Overview High Speed Heavy Duty CNC Milling and Drilling Machine for Flange Product Description The PMD-series is a gantr

Basic Info

| Hole Diameter | 50-100mm |

| Automatic Grade | Automatic |

| Precision | High Precision |

| Certification | GS, CE, RoHS, ISO 9001 |

| Condition | New |

| Spindle Model | Bt40/50 |

| Motor Power | 22kw Inverter Motor |

| Spindle Rotating Speed | 30-10000 Rpm/Min |

| Bed Material | Iron Casting |

| Transport Package | Standard Export Package |

| Specification | 3000*3000, 4000*4000, 5000*5000 |

| Trademark | Raintech |

| Origin | China |

| Production Capacity | 200e/Year |

Product Description

High Speed Heavy Duty CNC Milling and Drilling Machine for Flange

Product Description

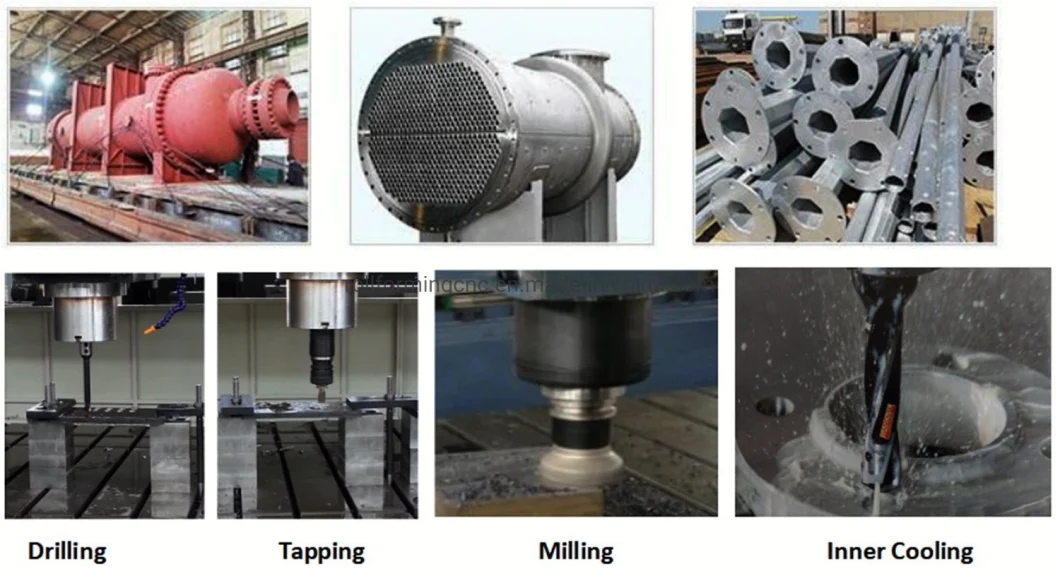

The PMD-series is a gantry moving CNC high-speed drilling and milling machine, mainly used for drilling, shaving, chamfering, grooves inside holes and milling of flanges, heat exchangers, tubeplates, rotary supports and other workpieces. It can be used for internal cold high-speed drilling with hard alloy drill bit or external cold drilling with high speed steel twist drill bit. Drilling depth of 10D (10x diameter) can be achieved with special crown drill bit. The machining process is NC and easy to operate. Adopting iron casting bed, it It can realize automatic, high precision and many kinds of mass production

CONSISTS OF THE BELOW ITEMS

Machine BodyWorking tableMoving Gantry Vertical sliding pillow type power headHydraulic systemPneumatic systemCooling systemCentralized lubrication systemElectrical control systemAutomatic chip removal systemTooling Changing SystemTHE PRODUCT STRUCTURE FEATURES

1.The machine mainly consists of the bed and the longitudinal slide table,gantry and the horizontal slide table,the vertical sliding pillow drilling power box,the work table,the electric control system,the hydraulic system,the cooling system,the chip system,the centralized lubrication system and so on.2. The machine adopts movable gantry and fixed worktable,save the floor area.3.The machine bed and worktable are independent,which improves the stability of the equipment and effectively reduces the vibration generated during high-speed drilling.4.The longitudinal and lateral movements of machine tools are guided by precision roller linear guide,which greatly increases the rigidity of the equipment.5.The spindle motor uses a special servo motor to drive the spindle through the synchronous belt, stepless speed regulation, low speed torque,can withstand heavy cutting load,and can be suitable for high-speed machining of hard alloy tools.6.The main axis of drilling is Taiwan precision spindle (internal cooling),the main axis cone hole BT50,with a butterfly springautomatic broaching mechanism,through the rod to install the drill or milling cutter,the hydraulic cylinder loose knife,the replacement tool is very convenient.Product Parameters

| Model | PMD-3030 | PMD-3030/2 | PMD-4040/2 | PMD-5050/2 |

| Processing(mm) | 3000×3000 | 4000×4000 | 5000×5000 | |

| Maximum thickness(mm) | 300 | |||

| Number of spindle | 1 | 2 | 2 | 2 |

| Spindle model | BT50 | |||

| Spindle speed(r/min) | 10-3000 | |||

| Feed stroke(mm) | 500 | |||

| Dia.of drilling hole(mm) | φ60 | |||

| Maximum tapping diameter(mm) | Optional M32 | |||

| Motor power(KW) | 22KW Inverter motor (18.5KW servo motor) | |||

Main difference between PHD&PMD

| Items | PHD-eries | PMD-Series |

Bed Material | steel plate welding | Gray Iron Casting |

| Gantry Moveable | Double servo motor double screw synchronous double drive | A dedicated servo motor drives the spindle through a timing belt |

| Power Head | Servo Slide Drilling Power Head | (Semi-enclosed) Ram type power head |

| Max.Tapping Diameter | M20 | M32 |

| Milling | yes | yes |

| Max.Drilling Diameter(mm) | Ø50 | ø100 |

| Secondary reamermachining for your tube sheet | Yes | No |

Detailed Photos

WORKSHOP

IRON CASTING BED

WORKPIECEHOT SELLING DRILLING MACHINE

Packaging & Shipping

Our Advantages

Professional Technical Team: We own a professional technical team who devote to the advanced design on the machines and better performance with plenty experience more than 15 years.Various Patents: we have been got many patents on various models of our products these years and keep on developing new products. High Products Quality:We have been gained a lot of good reputation among our customers and never got any quality complaint until now

Professional Experienced Sales Team:

Our sales team have average 10 years ' experience in export process, they are qualified to provide the most reasonable proposal for you and resolve your problems on machines selection and usage immediately once you ask.

FAQ

1. What's your advantage ?A: We assure each machine dispatched from our factory a long-life usage with easy operation and humane design.We consider help our customer to hence the production efficiency and save your human power as our aim.2. How l believe you?

A: Welcome to visit us to check our plant and ability, the payment method can be chosen and the third party inspection through Alibaba is available.3. What about the warranty of your products?

A: We provide 12 months warranty since the machine arrived at customer site , free charge of spare parts and oline maintenance service4. Where are you? Can l visit you?

A: our factory located in Shandong province, china, welcome to visit us at any time.5. How about the delivery time?

A: For standard model, the delivery usually 25 days since the advance payment receipt. For the customized products, the delivery time will follow our agreement with customer.We never receive any complain from our customers for the delivery time6. What kind of payment does your company support?

A: TT,100% LIC at sight,Cash, Western Union are accepted. If you have other payment terms, welcome discuss with us

Our Service

1. OEM DESIGN AND PRODUCTION:Our active engineer and design team can make the special machine according to your special requirement.2. DELIVERY IN TIME ASSURANCE:We assure the machines you ordered will be delivered at promised time3. YOUR PAYMENT PROTECTION:You can pay through Alibaba to protect your advance payment4. FREE INSTALLATION AND TRAINING:We provide the installation and training by online video support; local installation and training service team; send engineer for installation and training, installation operation video provided.Send to us