Large Heavy Strong 3 (4) Guideway Horizontal Roll (Roller) CNC Turning Lathe Manufacturer CK61125 CK61140 CK61160 CW61140 CW61160 6T-32T for Steel Plant

Basic Info

| Model NO. | CK61125 |

| Controlling Mode | CNC |

| Automatic Grade | Automatic |

| Setting Mode | Floor-type |

| Precision | Precision |

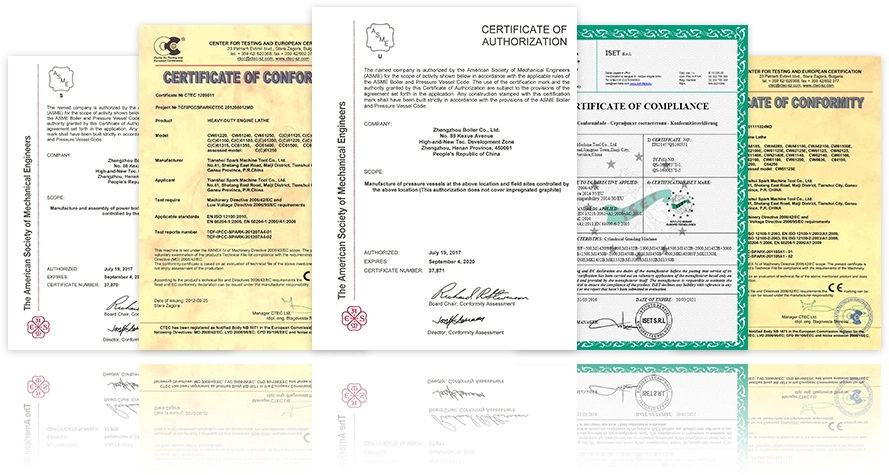

| Certification | CE, ISO 9001 |

| Condition | New |

| Swing Over Bed | 1250mm |

| Turning Length | 1500mm-8000mm |

| Width of Bed | 970mm |

| Spindle Bore | 130mm |

| Ce | Yes |

| Workpiece Weight | 8t/10t |

| Chuck Diameter | 1000mm |

| Tailstock Taper | Morse 6 |

| Tailstock Travel | 300mm |

| Transport Package | Wooden Case |

| Specification | swing over bed 1250mm |

| Trademark | ZT |

| Origin | China |

| HS Code | 84581900 |

| Production Capacity | 200 Sets/Month |

Product Description

Features:This machine has built-in features: strong power, good rigidity, high accuracy and excellent accuracy persistence. FANUC AC NC system ensures reliability of machine. It can be equipped with inspecting elements of pulse encoder and linear scale. Longitudinal and cross feed are separately realized by servo motor driving lead screw, which composes semi-closed circuit and full-closed circuit. And it has also features of CRT display, tool compensation, diagram display, failure diagnosis, programming when machine, and rapid programming with diagram display. Main drive system is by gear, automatic infinitely speed changing is by sliding gear. Saddle is coated with Turcite B of high wear resistance, which greatly increases service life and accuracy persistence of machine.

- One-piece machine bed design for high rigidity; Hardened guideway is of wear-resistance;

- Turcide B and forced lubrication system are used for the guideway;

Item | CK61100E | CK61125 | CK61140 | CK61160 |

Max. swing over bed | 1000mm | 1250mm | 1400mm | 1600mm |

Max. swing over carriage | 650mm | 900mm | 1060mm | 1240mm |

Max. Turning length | 1500~8000mm | 1500~8000mm | 1500~8000mm | 1500~8000mm |

Max. Workpiece weight between centers | 6000;8000kg | 8000;10000kg | 8000;10000kg | 8000;10000kg |

Width of bed | 755mm | 970mm | 970mm | 970mm |

Spindle nose | ISO A2-15 | ISO A2-15 | ISO A2-15 | ISO A2-15 |

Diameter of spindle front bearing | 200mm | 200mm | 200/220mm | 200/220mm |

Diameter of spindle bore | 130mm | 130mm | 130/100mm | 130/100mm |

Spindle taper | Metric No.140mm | Metric No.140mm | Metric No.120mm | Metric No.120mm |

Number of spindle speeds | Automatic; 2 ranges; stepless | |||

Spindle speed range (r/min) | 3.15-315;2.5-250;2-200/4-630 | |||

Main motor power | AC22/30~40kW | |||

Tool shank section | 45x45mm | 45x45mm/32x32mm | ||

Diameter of tailstock quill | 160mm | 200mm | 200mm | 200mm |

Taper of tailstock quill | Morse No.6 | Morse No.6 | Morse No.6 | Morse No.6 |

Travel of tailstock quill | 300mm | 300mm | 300mm | 300mm |

Weight of machine (3m length) | 12200kg | 14800kg | 15400kg | 13200(kg) |

Additional weight per 1 m BC | 800kg | 1200kg | 1200kg | 1200kg |

MACHINING ACCURACY:

- Roundness of finish turning surface: 0.010 mm

- Flatness of finish turning face: 0.030 mm / 300 mm

- Roughness of finish turning surface: Ra 1.6

- Pitch accuracy of finish turning threads: 0.025 mm / 50 mm

- Positioning accuracy: X: 0.030 mm; Z: 0.100 mm

- Repeatability positioning accuracy: X: 0.012 mm; Z: 0.025 mm

- Accuracy of size: IT6

- ACCESSORIES SUPPLIED WITH MACHINE:

- 4-JAW CHUCK, DIA. OF 1,000 MM: 1 SET

- STEADY REST, DIA. OF 50 TO 590 MM: 1 SETS

- LIGHTING DEVICE: 1 SET

- COOLANT DEVICE: 1 SET

- DEAD CENTER: 2 PIECES

- FOUNDATION BOLTS: 12 PIECES

- BALANCING LEVEL PADS FOR FOUNDATION: 12 SETS

Quality Control & Inspection before Packing

We control the assembly quality as well as control the quality of casting and parts/units to ensure the machines will be good enough from appearance to performance and stability keeping.

After testing and painting before packing, we will check all the accessories item by item:Packing & Local Transportation & Fixing

Normally we will pack the machines with fumigated wooden cases or poly wooden case and steel pallets. When the machines are loaded into the container, fixing job will be done to ensure the sea shipment safety.

FAQ 1. How can I choose the most suitable machines?

A: You can choose the exact model by yourself. Or you can tell us your specifications, to let us choose the best model for you, too.

You can also send us the product drawing, and we will choose the most suitable machines for you. . 2. When do you deliver?

A: It depends on the machine and model you choose. Mostly 1.5 months - 3 months. All machines are 100% new and not used, only made according to your order. Occasionally there will be a few machines available from stock. You can send us a message or mail to check exact delivery time.

3. Is machine tested?

A: The accuracy, noisy will be tested according to China GB standard. Some machines will 4. What is your trade terms?A : FOB, CFR and CIF all acceptable. 5. What's the Payment Terms?A : T/T 30% down payment when order ,70% balance payment before shipment ;Irrevocable L/C at sight also acceptable.

6. Do you accept cash or L/C?

A: We accept T/T or L/C, all through banking system. We do not accept cash, 'cause we are an official registered company that all payment must go through official bank account.

7. What's the MOQ?

A: 1 set (Only some low cost machines will be more than 1 set)

8. How is the warranty?

A: 12 months after shipment date

9. If I have a problem setting up/ getting it running problem, will you be available by email to assist in solving the problem.A: Video technical support, online service, we can answer you in 24 hours.