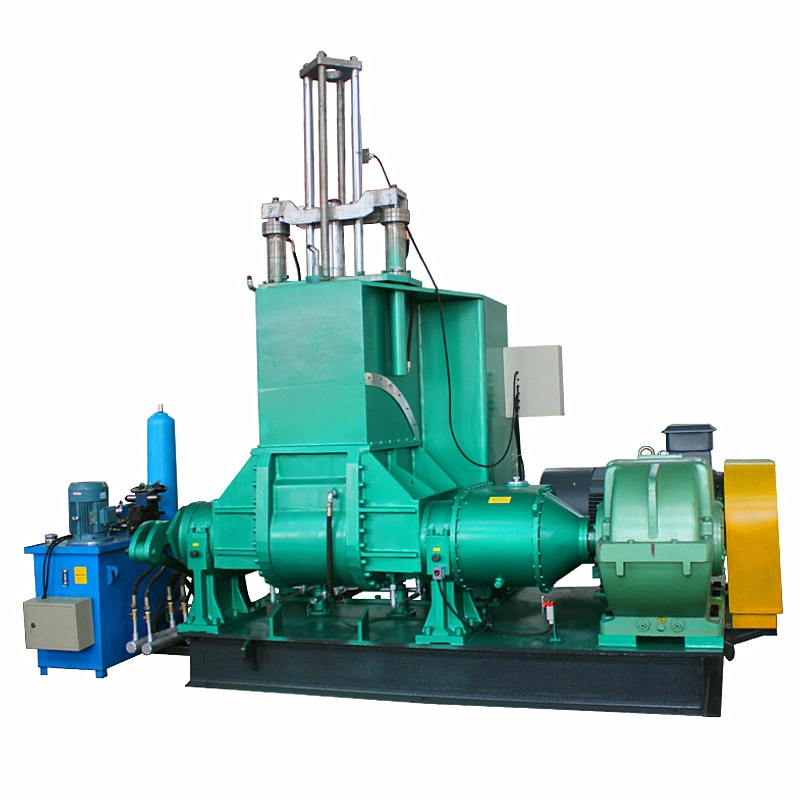

Automatic Rubber Dispersion Kneader Mixer Internal Mixing Banbury Machine EVA Kneader Machine

Basic Info

| Model NO. | XSNM |

| After-sales Service | Engineers Available to Service |

| Warranty | 2 Years |

| Control Type | PLC |

| Automatic Grade | Automatic |

| Power Source | Electric |

| Type | Rubber Mixer |

| Drive Motor | 3.75kw |

| Turning Angle | 110 |

| Water Cooling | 0.2-0.4MPa |

| Electric Heating | 1kw |

| Function | Rubber Kneader |

| Stirrer Type | Sigma Kneader |

| Motor | Siemens Brand |

| The Rotors | Chroming Carbide Alloy |

| Reducer | Hardness Tooth Surface |

| Certification | CE/SGS/ISO |

| Feeding Method | Front Door and Back Door |

| Core Components | Gearbox, Motor |

| Transport Package | in Standard Export or According to Customers Reque |

| Specification | 35-55-75-90-110-150L |

| Trademark | Evertech |

| Origin | Shandong, China (Mainland) |

| HS Code | 84778000 |

| Production Capacity | 50 Set/Sets Per Month |

Product Description

35L 55L 75L Rubber Kneader / Rubber Internal Mixer Machine

Contact:Victoria

Brief Introduction:

Be usable for rubber or plastic plasticzing and mixing or rubber and plastic blending,warmly welcome to visit our factory for more details.

Features:

1. Rubber or plastic stock can be plasticized or mixed in a closed and pressurized space with the temperature controlled

2. Optimization of the parameters such as the helical angle of rotor wings and the wing overlap length brings about even distribution of the stock.

3. The rotor wings are built up by welding with the abrasion-proof carbide alloy to resist abrasion and corrosion.

4. All the parts of rubber kneader machine in contact with stock are of the jacket design.

5. Stock is fed through the rear door of the framework (or another port) and discharged by the mixing chamber tilting forward by 140°.

Technical parameter:

1.Type | X(S)N-35X30 | X(S)N-55X30 | X(S)N-75X30 | X(S)N-110X30 |

2.Pinching total cubage(L) | 75 | 125 | 175 | 250 |

3.Dense smelting total cubabe(L) | 35 | 55 | 75 | 110 |

4.Main motor power(kw) | 55 | 75 | 110 | 185 |

5.Overturn motor power(kw) | 4.0 | 4.0 | 4.0 | 5.5 |

6.Overturn angle(degree) | 140 | 140 | 140 | 140 |

7.Rotate speed of rotor axis(r/min) | 30/24.5 | 30/24.5 | 30/24.5 | 30/24.5 |

8.Pressure of compression air(MPA) | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 |

9.Pressure of cooling water(MPA) | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 |

10.Pressure of heating water(MPA) | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 |

11.Overall dimension(L*W*H)(mm) | 3200*1900*2900 | 3300*1900*2945 | 3760*2143*3135 | 4075*2712*380 |

12.Weight(kg) | 6500 | 7800 | 10230 | 14970 |

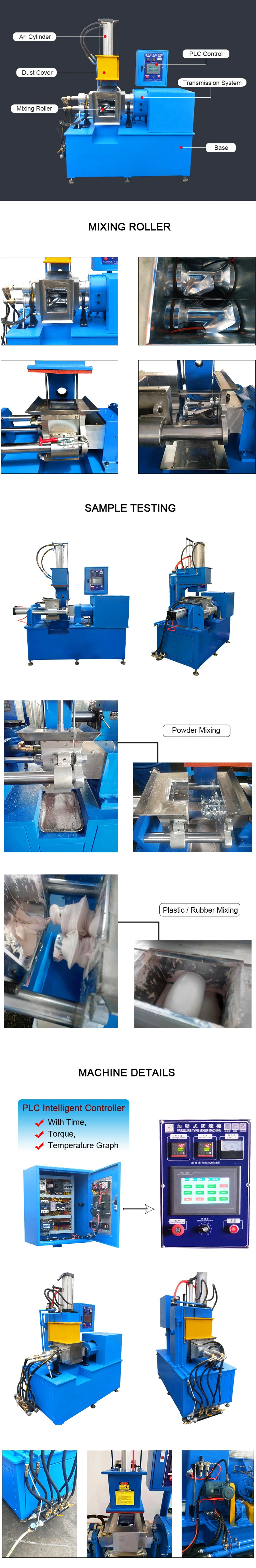

1. Pneumatic Control System

Controlled by PLC instruction, a bi-directional air cylinder make the ram up or down. In case that overload occurs in the mixing chamber, the top ram can be raised automatically or manually if necessary, so as to protect motor overload.

2. Electric Control System

Adopt imported PLC device and eletric control components which are all imported products or imported technology products are adopted in the electric control system as to raise control reliability.

3. Tilting Mechanism

This mechanism is powered by a motor (3.0KW), driven by a hydraulic station, coupling, electromagnetic directional valve, hydraulic cylinder, etc. to drive the mixing chamber to turn 140 ° around the front rotor axis, and is equipped with two travel switches.

4. Main Driving System

The part is made up with main rotor,reducer,connecting gears.It realizes odd-speed rotation of the rotors with running face one other.

5. Mixing Chamber

It consists of a "W" shape body and two side board made of high quality steel plates by means of extrusion forming and welding, which are jacked to take the flow of cooling water or steam.It is plated with hard chrome on its internal walls.

6. Thermal Resistance

There is a plug-in thermal resistance in middle section of the bottom of the chamber to be connected to electrical system to inspect and display the temperature.

7. Dust Sealing Device

At the joint between the top of the mixing chamber and the cantilevered arm of the machine frame, the dust sealing assembly with curved slotted partings are used obtaining an excellent and reliable sealing purpose.

8. Cooling/Heating System

A common piping system is adopted for either cooling or heating materials in mixing operation.Through the system cooling water or steam is fed in three ways to the cavities of the rotors bladers, the jackets of the mixing chamber and the top ram.

9. Rotor:

It is designed to the hollow bladers of banbury type, the follows are connected with axial hole of rotor shaft used as cooling or heating passage.

Reference photos:

Customer VisitCompany Information

Qingdao Evertech Industry is a professional pressure vessel designer, manufacturer and exporter. We have manufacturing licenses for ASME U, ASME U2,NB,PED, D1, D2 and A2 pressure vessels. Composed of more than 20 senior experts and professional engineers, the research and development team, with more than 20 years of professional experience, is committed to product design, development and program optimization, and can provide high-quality solutions according to users' requirements in different operating conditions. Company has cover an area of 70000 manufacturing base and 15000 modern manufacturing plants, can provide customers both at home and abroad with composite autoclave, high pressure autoclave, high pressure reactor, AAC autoclave, deaerator, pouring tank pressure vessel products such as more than 800 sets, pressure vessel head more than 20000 sets high quality products and services, won widespread praise.

Welcome to place an order.100% Real ManufacturerWelcome to send me email any time.

Contact : Victoria