Horizontal Flat Bed Precision Metal Turning CNC Lathe Machine Ck6150

1. Integral casting for bed and foot.2. High rigidity, high precision, high speed independent spindle, through hole is Ф

Basic Info

| Model NO. | CK6150 |

| Power Source | Electric |

| Controlling Mode | CNC |

| Automatic Grade | Automatic |

| Setting Mode | Floor-type |

| Precision | High Precision |

| Certification | ISO 9001 |

| Condition | New |

| Max Swing Over Bed | 500mm |

| Center Distance | 1000/1500/2000mm |

| OEM | Yes |

| Spindle Nose Type | A2-8 |

| Speed | 45-260/140-800/280-1600 |

| Motor | 7.5kw |

| Bar Diameter | 82mm |

| X Axis Travel | 210mm |

| Z Axis Travel | 390mm |

| Manual Chuck | 250mm |

| Through Hole of Chuck | 80mm |

| Color | Customization |

| Working Length | 1000 |

| Electric Tool | 4 Position |

| X/Z Rapid Feed | 4/8m/Min |

| Transport Package | Wooden Package |

| Specification | 2800/3300/3800*1600*1700mm |

| Trademark | JOINT |

| Origin | Shenzhen, China |

| HS Code | 8458110090 |

| Production Capacity | 30 Sets |

Product Description

1. Integral casting for bed and foot.2. High rigidity, high precision, high speed independent spindle, through hole is Ф82mm.3. Motor direct drive with variable speed .4. Optimized structure, good accuracy and super stability.

| Model | CK-6150 | ||||

| Main parameter | Max. swing over bed | mm | 500 | ||

| Center distance | mm | 1000/1500/2000 | |||

| Max. processing length (from chuck to center) | mm | 850/1350/1850 | |||

| Max. turning diameter | Disk | mm | 500 | ||

| Axis | mm | 290 | |||

| Max. swing over slide | mm | 290 | |||

| Spindle and chuck parameters | Spindle speed (Variable) | Low speed | rpm | Manual shift | 45-260 |

| Medium speed | rpm | 140-800 | |||

| High speed | rpm | 280-1600 | |||

| Spindle max output torque | NM | 600 (7.5kw) | |||

| Spindle nose type | type | A2-8 | |||

| Through bar diameter | mm | Φ82 | |||

| Manual chuck and through hole | mm | Φ250 (Φ80) | |||

| Spindle motor power | kw | 7.5 Variable frequency motor | |||

| Feed part parameters | Spacing of guide rail of Z axis | mm | 390 | ||

| Spacing of guide rail of X axis | mm | 210 | |||

| X axis stroke | mm | 295 | |||

| Z axis stroke | mm | 1000/1500/2000 | |||

| X/Z axis rapid feed speed | m/min | 4/8 | |||

| X axis servo motor torque | NM | 6 | |||

| Z axis servo motor torque | NM | 10 (Body above 1500 15NM) | |||

| Knife tower | Electric tool rest form | type | 4-station vertical type (optional 6-station horizontal type or knife arrangement) | ||

| Tool specification | mm | 25*25 | |||

| Tailstock | Tailstock quill diameter | mm | Φ75 | ||

| Tailstock quill stroke | mm | 120 | |||

| Shape | Tailstock quill taper | mm | MT-#5 | ||

| Dimension | mm | 2800/3300/3800*1600*1700 | |||

| Weight | kg | 3100/3500/3900 | |||

1. GSK 980TC3 controller system2. Spindle and motor3. Four position tool turret4. Three jaw manual chuck5. Working light6. Lubrication system7. Level pad8. Tool and tool box9. Operation manual

Optional accessories:

1. Fanuc controller system2. Six position tool turret3. Hydraulic tail stock4. Solid hydraulic chuck5. Hollow hydraulic chuck

Company Profile

Shenzhen Joint Technology specializes in R&D and manufacturing mold processing and machinery parts processing equipment, we developed high quality and high-tech research, development, manufacturing, service team and management system, and expanded products to more than 11 series from milling machines, to machine center,mechanical arm, automation. With the exceptional quality products and distinct brand reputation, our products are sold to more than 40 developed cities all over China, and also to more than 20 countries all over the world across Asia, Europe and America.Our company takes the high quality product as orientation, R&D ideas is to provide customers with the most suitable quality products, became a professional machine tool manufacturer with a complete product line of mould and parts processing machine tool and strong tailor-made design capability in China.

Core strengths

1. Standardize processes and operating mechanisms, high standards production and testing software and hardware - Ensure stable product supply and service support.2. We insist in-depth research and technological precipitation for more than 20 years - Promote rapid innovation and progress in products and technology.3. Comprehensive information management systems such as ERP and CRM - JOINT has formed a efficient operation and continuous improvement system.4. Integrity, collaboration, innovation, and win-win spirit - we JOINT has established a strong and stable supply chain, and a large long-term win-win customer base.

Special advantages

1. Provide more practical customized products2. Provide CNC product applications support3. Provide integrated solution for auto production line4. Provide integrated design of mold, and parts processing production line

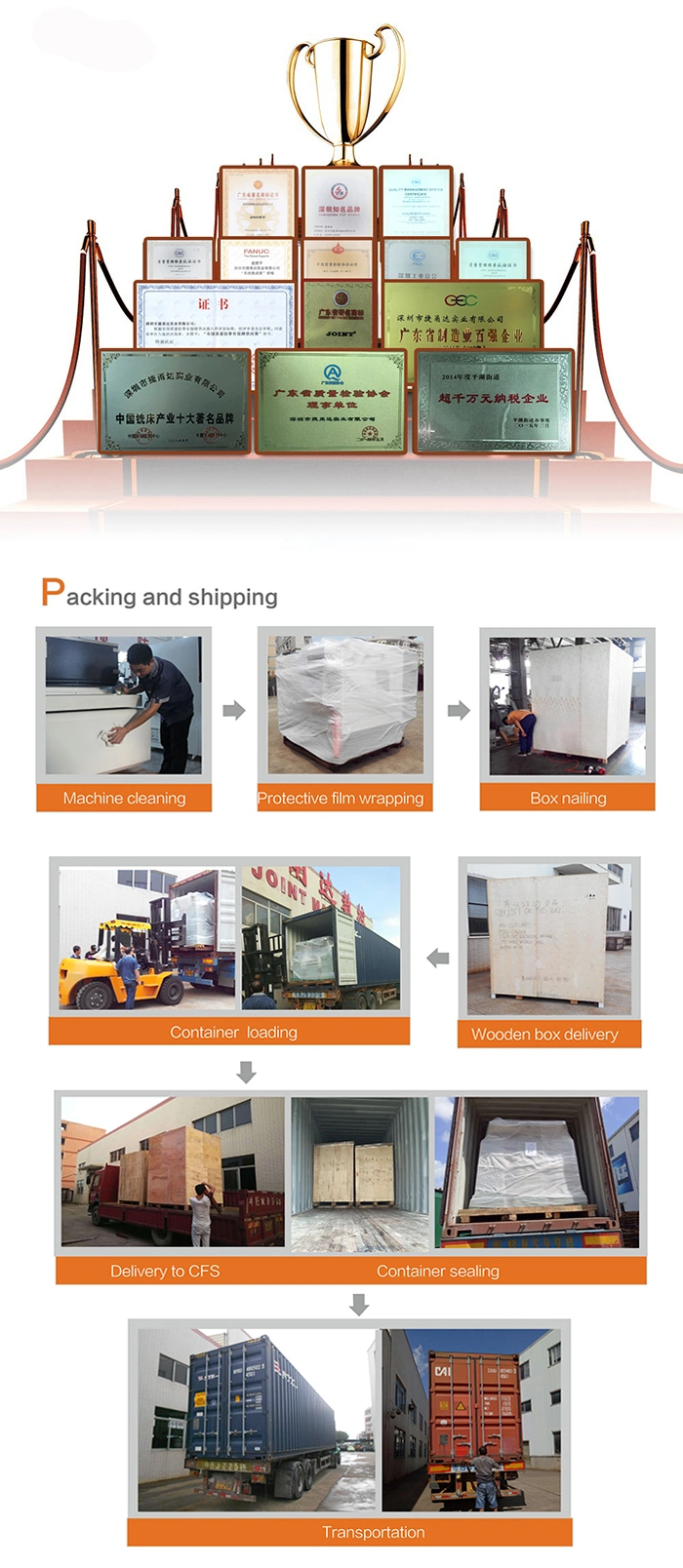

1. National High-tech Enterprose2. Shenzhen famous brand "JOINT"3. Member of China Quality Association4. Member of China Machine Tools Association5. Vice-chairmen of Shenzhen Machinery Association6. CE certification on milling machine, grinidng machine and machine center.7. More than 150 patents on invention, utility model patent and software copyright etc.8. Guangdong famous trademark

FAQ

Q1: Are you trading company or manufacturer?A1: We are factory.Q2: What is your terms of payments?A2: 30% as deposit, 70% should be paid before delivery.

Q3: How can I choose the most suitable machines?A3: Please tell us your requirements of the machines, or you could send us the products drawing, our engineer can help to choose suitable model for you.Q4: What is the package? Is it suitable for shipment?A4: Machine will be packed by exporting standard package, water proof and anti-rust. It is very much strong for oversea transportation.Q5: How long is the warranty for machines?A5: Warranty time is 12 months. We will supply the repair parts in this warranty time. The charge of repair parts will be free due to its quality problemin this guarantee.

Send to us