GSK 25iMC Series 5-Aixs Linkage CNC System, CNC Controller for machining center

Overview Package size per unit product 55.00cm * 39.00cm * 460.00cm Gross weight per unit product 20.000kg iProduct Desc

Basic Info

| Model NO. | GSK 25iMC |

| Process Usage | Metal-Cutting CNC Machine Tools, CNC Non-Conventional Machine Tools, Metal-Forming CNC Machine Tools |

| Movement Method | Contour Control |

| Control Method | Closed-Loop Control |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.0001mm |

| Performance Classification | High-End CNC Machine Tools |

| Certification | CE, ISO 9001, ISO 50001:2018;ISO45001:2018;Is014001:2015; |

| Condition | New |

| Type | CNC Controller |

| Materia | Metal |

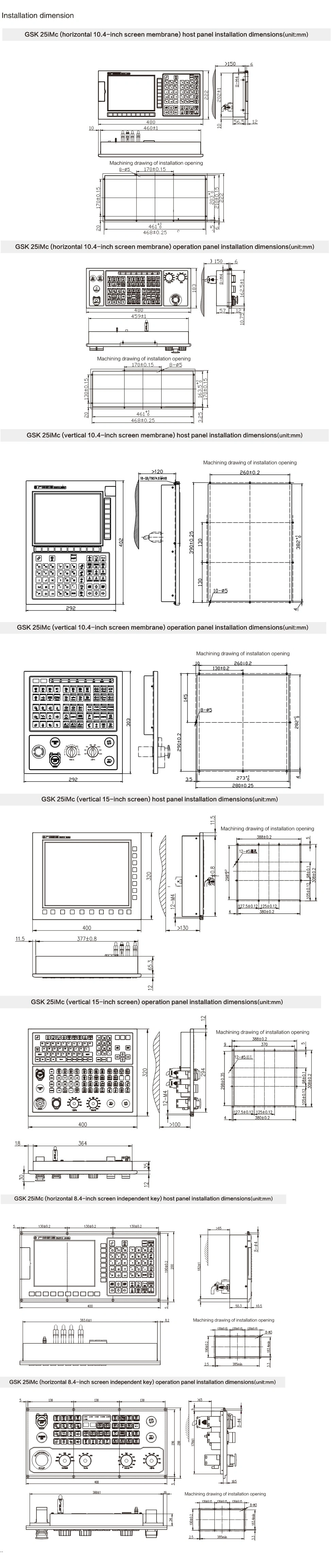

| Displayer | 8.4 or 10.4 or 15-Inch LCD Display |

| Linkage Axes | 4 or 5-Axis Linkage |

| Rtcp Function | Tool Center Point Control G43.4 |

| Program Storage | 4G Memory,up to 400 Programs |

| Support | Online Support |

| Transport Package | Carton or Plywood |

| Specification | small |

| Trademark | GSK |

| Origin | Guangzhou, China |

| HS Code | 8537101901 |

| Production Capacity | 100000sets/Year |

Packaging & Delivery

Package size per unit product 55.00cm * 39.00cm * 460.00cm Gross weight per unit product 20.000kgProduct Description

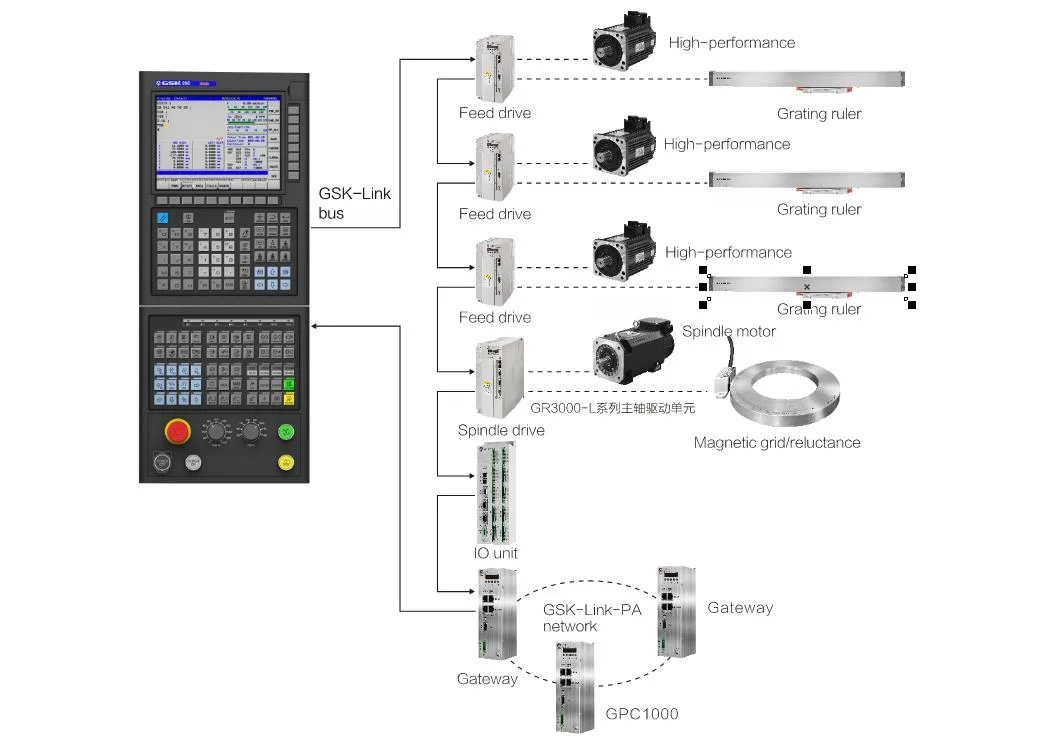

iProduct DescriptionGSK 25i is a new generation of high-performance and high-reliability CNC system developed through continuous innovation and improvement. It integrates cutting-edge technologies in the field of CNC today, with powerful functions, convenient operation and wide application range.

GSK 25i boasts the new-generation CNC controller, faster data processing speed, higher system stability, stronger control functions, multi-axis linkage, bus control, high speed, high precision and absolute encoder.

This series of products have been widely used in automobile manufacturing, energy, power, hardware mold, 3C and other industries, providing efficient and accurate motion control and process solutions for various industries.

Adaptive control of feed rate for 5-axisside edge machining Pitch compensation

*Load the REN file selected for the corresponding axis with one key to quickly complete the pitch compensation parameter setting and pitch compensation data writing;*The user can carry out one-key incremental loading according to the actual demand to achieve the effect of correction and compensation;*Realize zero operation of pitch compensation parameters and data, completely avoid data errors or careless mistakes caused by manual setting, and strictly control the accuracy of data.

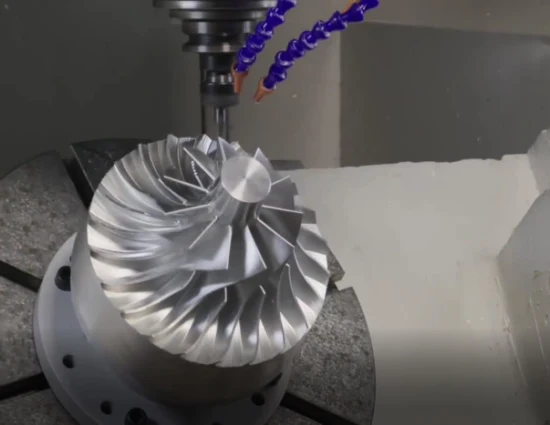

5-Axis machining with RTCP(optional)

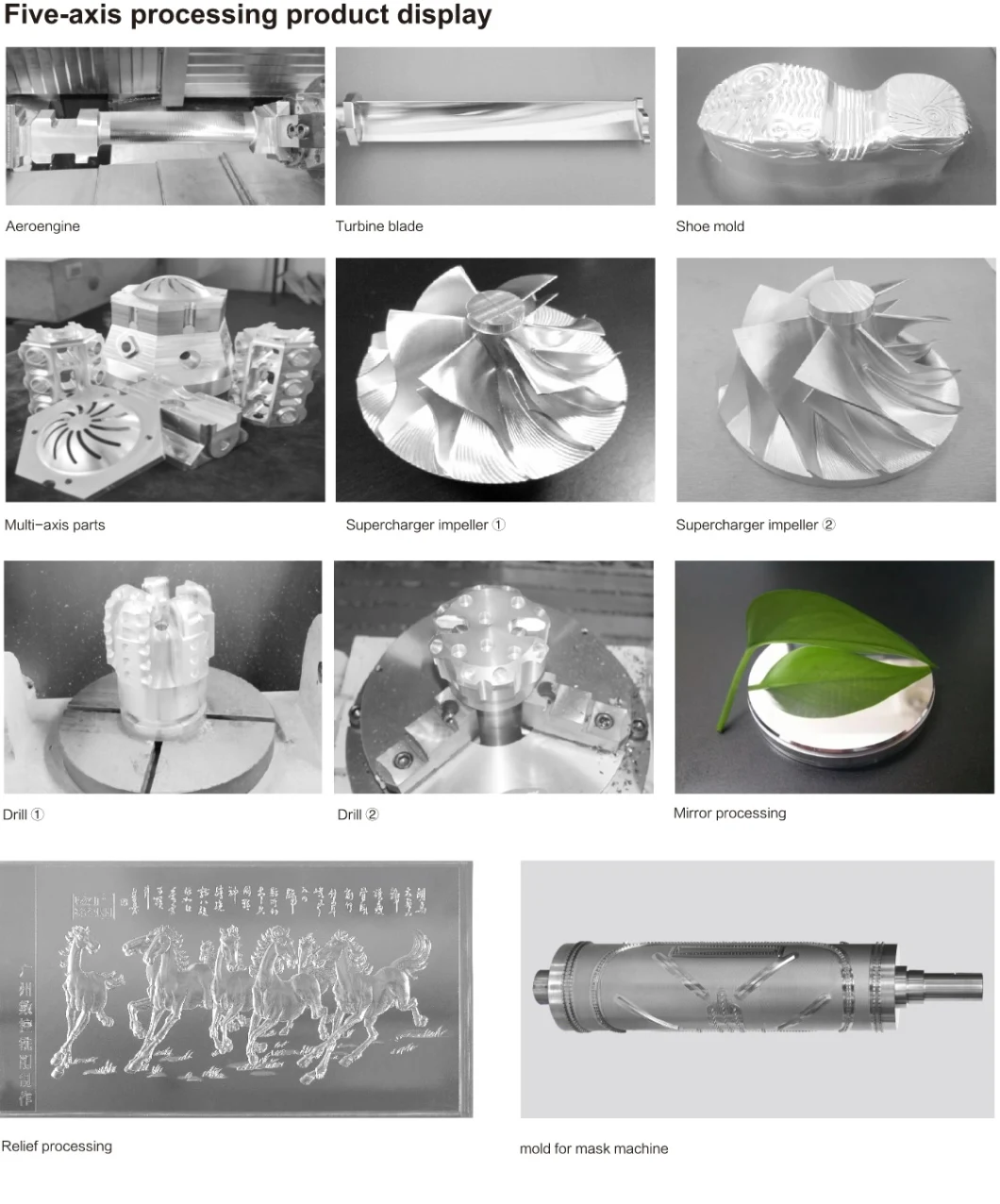

8-axis and 5-linkage, supporting various types of five-axis machine tool structures, suitable for the processing of multi-axis parts such as aeroengine, steam turbine blade and mold, with the functions of five-axis RTCP (tool center point control), inclined plane (3+2 positioning), five-axis tool path fairing, adaptive control of feed rate for five-axis side edge processing, fiveaxis hand pulse insertion, to meet customers'requirements for various multi axis processing functions and processing quality.Technical features

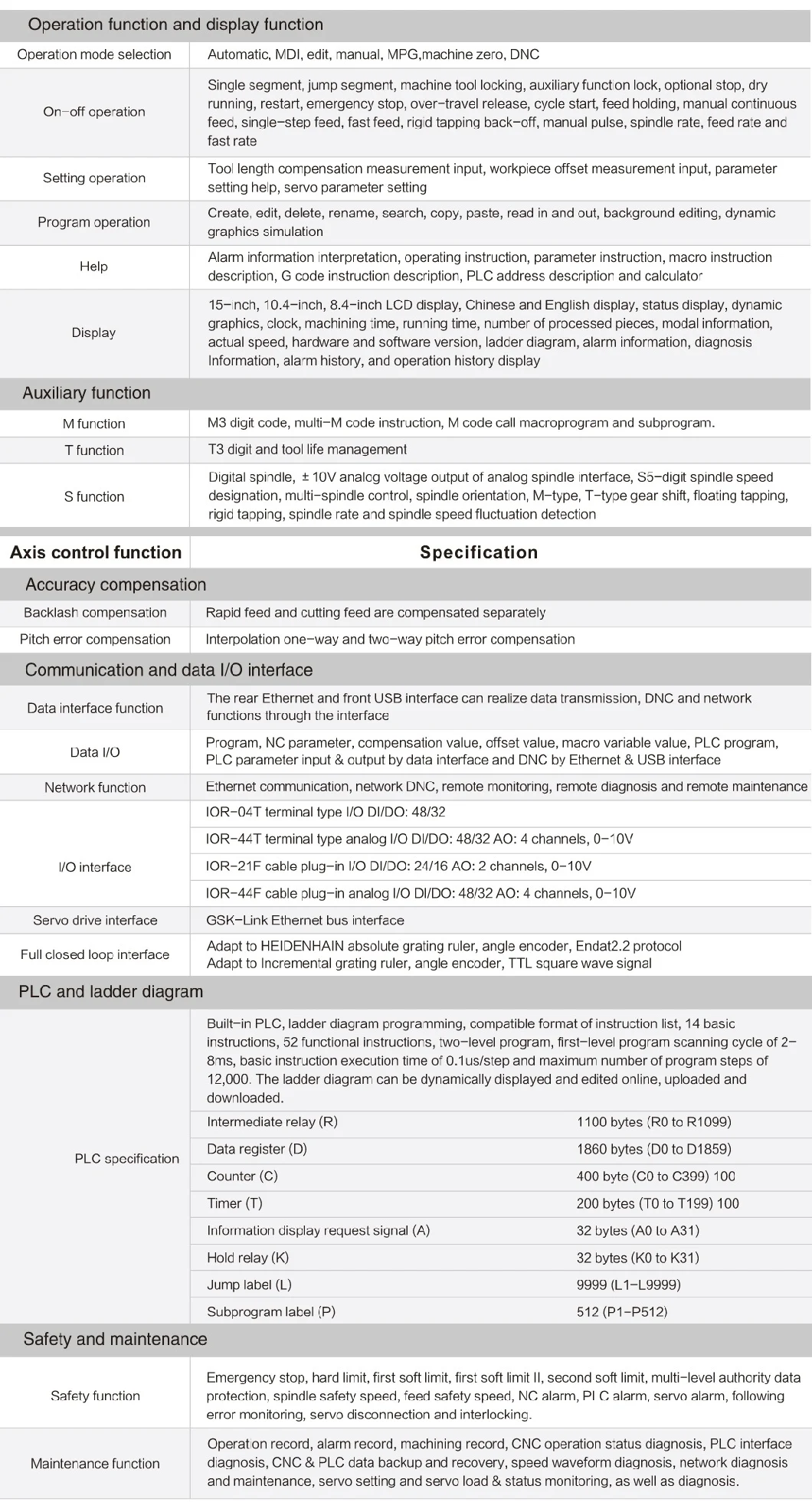

| Axis control function | Specification | |||

| Axis control function | ||||

| Maximum number ofcontrol axes | 8 feed axes plus 2 servo spindles | |||

| Number of linkage axes | 4-axis linkage | |||

| 5-axis linkage | ||||

| Number of controlled PLC axes | Up to 8 axes | |||

| Synchronous controlof feed axis | Up to 4 groups | |||

| Closed loop control | Support incremental, absolute encoder or grating ruler | |||

| Minimum instruction unit | Minimum instruction unit IS-B | 0.001mm | 0.0001inch | 0.001° |

| Minimum instruction unit IS-C | 0.0001mm | 0.00001inch | 0.0001° | |

| Minimum detection unit | Minimum instruction unit IS-B | 0.001mm | 0.0001inch | 0.001° |

| Minimum instruction unit IS-C | 0.0001mm | 0.00001inch | 0.0001° | |

| Maximum instruction value | +999999.9999mm+99999.9999inch+999999.9999° | |||

| Maximum feed speed | Maximum feed speed 200m/min | |||

| Automatic accelerationand deceleration | Linear before interpolation, S-curve acceleration/deceleration, jerk control | |||

| High-speed and high-precision machining | G05 high-speed small line segment look-ahead interpolation, path smoothing, and up to 1000 look-ahead and read-ahead segments | |||

| 5-axis control function(optional) | ||||

| RTCP function | Tool center point control G43.4 | |||

| Inclined surface machining | Five-axis positioning (3+2) machining G68.2 | |||

| Five-axis manual feed | Manual feed in tool axis, right angle direction of tool axis and rotation direction of tool center point | |||

| Programming function | ||||

| Program format | ISO instruction standard, program name: 0+4 digits, segment number N+5 digits, G+3 digits,coordinate value lP 6 digits before the decimal point, coordinate value lP : 4 after the decimapoint, S+5 digits, T+3 digits, M +3 digits, F+6 digits before the decimal point and F+4 digits after thedecimal point | |||

| Interpolation function | 48 groups of basic coordinate system G52-G59 and additional extended coordinate system (G54.1) | |||

| Workpiece coordinate system | 48 groups of basic coordinate system G52-G59 and additional extended coordinate system (G54.1) | |||

| Tool compensation | C tool compensation function. 400 sets of tool compensation | |||

| Programming function | There are more than 100 G instructions in total, including 12 common fixed cycles, 19 special fixedcycles and compound cycles, face milling, coordinate system rotation, scaling, mirroring, automatictool length measurement, tool center point control, and inclined surface machining commands. Thenumber of subroutine calls is 4, and the user macro program is type B | |||

| Program storage | 4G Memory,up to 400 programs | |||

| Reference point function | G27 returns to reference point to check: G28 returns to reference point;G29 returns from the reference point; G30 returns to reference points 2, 3 and 4 | |||

| Skip function | G31 skip function for tool and workpiece measurement | |||

| Programmable control function | Programmable stroke limit (G22 and G23), programmable data input (G10) | |||

Company Profile

GSK CNC Equipment (hereinafter referred as GSK) is specially devoted to conducting research and practice of basic equipment industrial development, providing "trinity" packaged solutions of machine tool CNC system, servo drive and servo motor, taking initiative in the expansion of industrial robot and all-electric injection molding machine field, developing the new marketing mode of machine tool exhibition hall, providing the customers with all-round professional machine tool remanufacturing solutions and services, promoting the integration of production and education, setting up the vocational education and training institute, as well as conducting highly skilled CNC personnel training. It has developed into a high-tech enterprise integrating science, education, industry and trade, thus being known as "China Southern CNC Industrial Base". Adhering to the corporate philosophy of "making itself a century-old enterprise and building gold quality" and the service spirit of "keeping improvement and making users satisfied", GSK enhances the user product value & benefits through continuous technological progress and innovation, and makes unremitting efforts to promote the localization process of basic equipment industry, improve the technological level of the industry, and promote the development of China's national equipment manufacturing industry.

Main products:

GSK CNC System Idustrial robot

Full electric injection molding machine CNC machine

our partners

218MC USB Reading Problem Solution

218MC USB Reading Problem Solution

Send to us