Wz CNC Heavy Duty Horizontal Lathe/Machine

Basic Info

| Model NO. | WZ900 WZ1250 WZ1600 WZ2000 |

| Power Source | Hydraulic Pressure |

| Controlling Mode | CNC |

| Automatic Grade | Automatic |

| Setting Mode | Floor-type |

| Precision | High Precision |

| Certification | ISO 9001 |

| Condition | New |

| Power Supply | 380V/415V |

| Temperature | 5- 40° C |

| Relative Moisture | Less Than 85% |

| Workshop Environment | No Dust, No Harmful Gas/Liquid |

| Transport Package | Wood |

| Specification | iron |

| Trademark | WZ |

| Origin | China |

| HS Code | 8458110000 |

| Production Capacity | 50 |

Product Description

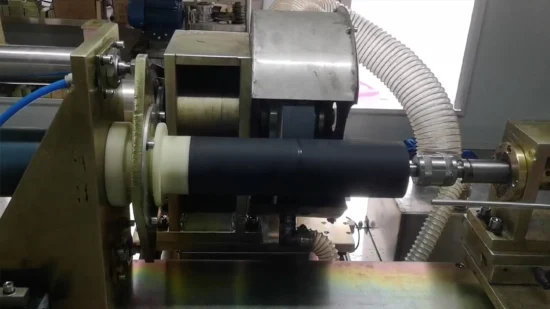

APPLICATION

WZ series adopts modular design, with advantages of heavy load, high accuracy, efficiency and reliability, rational structure, wide application and convenience operation. Besides the basic functions of common heavy duty horizontal machine tools, it can process conical surface, curve surface, step axle groove and thread. It can also realize milling, drilling and grinding when equipped with different kinds of attachments.lt is mainly applied in industries such as energy, transportation, machinery, for machining shaft of wind power, generator, rotor of water turbine, diesel cylinder for ship, cross pin, connecting bar, cylinder rod, roller, mechanical shaft, rudder spindle, hoister and barrel of ship.

The main performance characteristics:

- Headstock spindle adopts high accuracy rolling bearing at radial and axial direction. Two step mechanic speed change, AC spindle motor drive. Master and slave servo motors could be adopted for milling feeding and indexing;

- Tailstock adopts self-adapt mechanism of workpiece thermal extension, electric load cell and teeth plate thrust device;

- At lengthwise direction, carriage adopts plastic paste soft belt guideway, at crosswise direction, linear roller sliding way.

- Lengthwise transmission adopts double rack and pinion mechanism for clearance elimination crosswise transmission adopts double nut clearance elimination mechanism and ballscrew. Vertical. horizontal or motorized turret carriage could be adopted;

- Optional attachments :C type steady rest, milling tool carriage, grinding head, deep-hole boring system with large diameter, etc;

- Optional CNC system: SIEMENS, FANUC, REXROTH etc.

Product Parameters

| Item | Unit | Model | |||

| WZ900 | WZ1250 | WZ1600 | WZ2000 | ||

| Max swing diameter | mm | 1250 | 1600 | 2000 | 2500 |

| Max. machining diameter over | mm | 900 | 1250 | 1600 | 2000 |

| Max. loading capacity between centers | t | 18/25 | 18/25 | 18/25/32 | 18/25/32 |

| QTY of bed guideway | 3+1 | 4 | 4 | 4 | |

| Bed width | mm | 1100 | 1100 | 1505 | 1705 |

| Front bearing diameter of spindle | mm | 240 | 240 | 240 | 240 |

| Main motor power | kW | 60/100 | 60/100 | 60/100 | 60/100 |

| Spindle max torque | kNm | 18-39 | 18-39 | 18-39 | 18-39 |

| Max spindle speed | r/min | 800 | 800 | 800 | 800 |

| Spindle mechanic shift QTY | n° | 2 | 2 | 2 | 2 |

| Cross slide travel | mm | 580 | 750 | 750 | 950 |

| Y axis adjusting range | mm | ±50 | ±50 | ±50 | |

| Tailstock sleeve diameter | mm | 230/300 | 230/300 | 230/300 | 230/300 |

| Motorized tool-motor power | kW | 11 or 15 | 11 or 15 | 11 or 15 | 11 or 15 |

Detailed Photos

Workshop

Package

Installation and commissioning