Ck-6150-1m 1 Meter Slant Bed CNC Lathe CNC Machine

Basic Info

| Model NO. | CL-6150-1M |

| Process Usage | Metal-Cutting CNC Machine Tools, CNC Non-Conventional Machine Tools, Metal-Forming CNC Machine Tools |

| Movement Method | Linear Control |

| Control Method | Semi-Closed Loop Control |

| Numerical Control | CNC/MNC |

| Processing Precision | ±0.003mm |

| Performance Classification | High-End CNC Machine Tools |

| Certification | SGS |

| Condition | New |

| The High of The Bed Center | 250mm |

| Maximum Turning Diameter | 500mm |

| X Axis Travel Distance | 290mm |

| Workpiece | 750mm |

| Transport Package | Wooden Box |

| Specification | 2625x1414x1815mm |

| Trademark | LiSN |

| Origin | China |

| HS Code | 8458110090 |

| Production Capacity | 10000 Pieces/Year |

Packaging & Delivery

Package size per unit product 262.50cm * 141.40cm * 181.50cm Gross weight per unit product 2600.000kgProduct Description

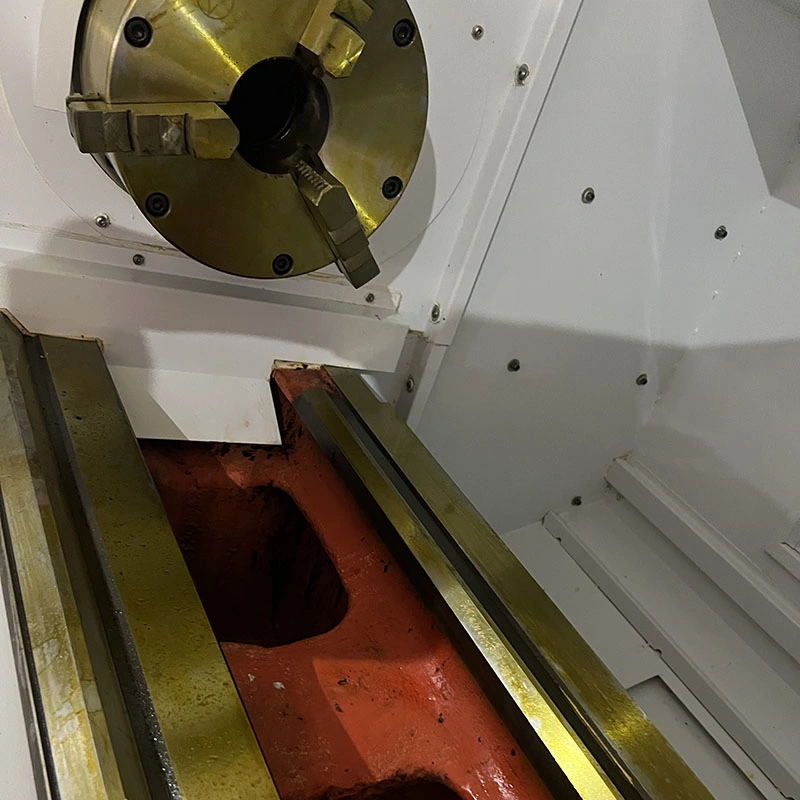

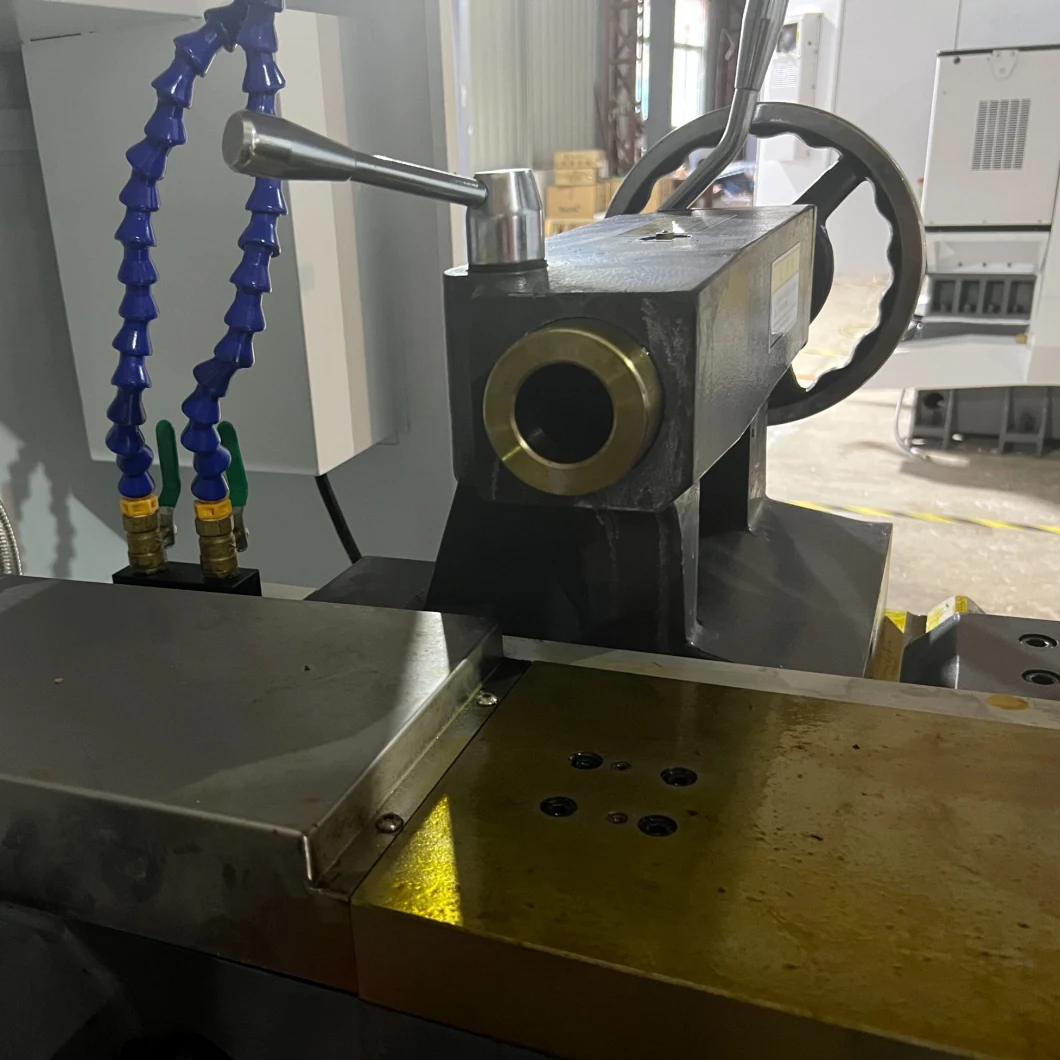

CL-6150-1M is a 1 meter high performance Horizontal slant bed CNC lathe with high rigidity, high stability and high acurracy. The maximum rotary diameter of bed body is φ500mm and the Maximum swing diameter on board is φ260mm. The maximum length of workpiece is 1000mm, 1500mm and 2000mm and the maximum turning diameter of the machine is φ500. The machine body castings are made of high strength and high stability material, which provides high stability for the machining process. The excellent casting and making process also extends the use of the machine and ensure there are no nay deformation and rust problems. The machine is equipped with a safety door, which can protect the safety of employees in the process of processing and protect the surrounding environment. The machine control system is CNC 980TB3i model from Guangzhou CNC, the interface operation is simple, which can greatly improve the processing efficiency and reduce the processing cost.

Main Features

- Excellent stability

- Excellent rigidity

- High performance

- Safety gate

- Maximum rotary diameter of bed body: φ500

- Maximum swing diameter on board: φ260

- Maximum length of workpiece: 1000mm, 1500mm and 2000mm

| Main Technical Parameters LiSN-1000 | |||

| Items | Unit | Parameters | |

| Maximum rotary diameter of bed body | mm | φ500 | |

| Maximum swing diameter on board | mm | φ260 | |

| The high of the bed center | mm | 250 | |

| Maximum length of workpiece | mm | 750 | |

| 1000 | |||

| 1500 | |||

| 2000 | |||

| Maximum turning diameter | mm | φ500 | |

| X Axis travel distance | mm | 290 | |

| Z Axis travel distance | 1000 | mm | 800 |

| X/Z rapid feed rate | mm/min | 3800/7600 | |

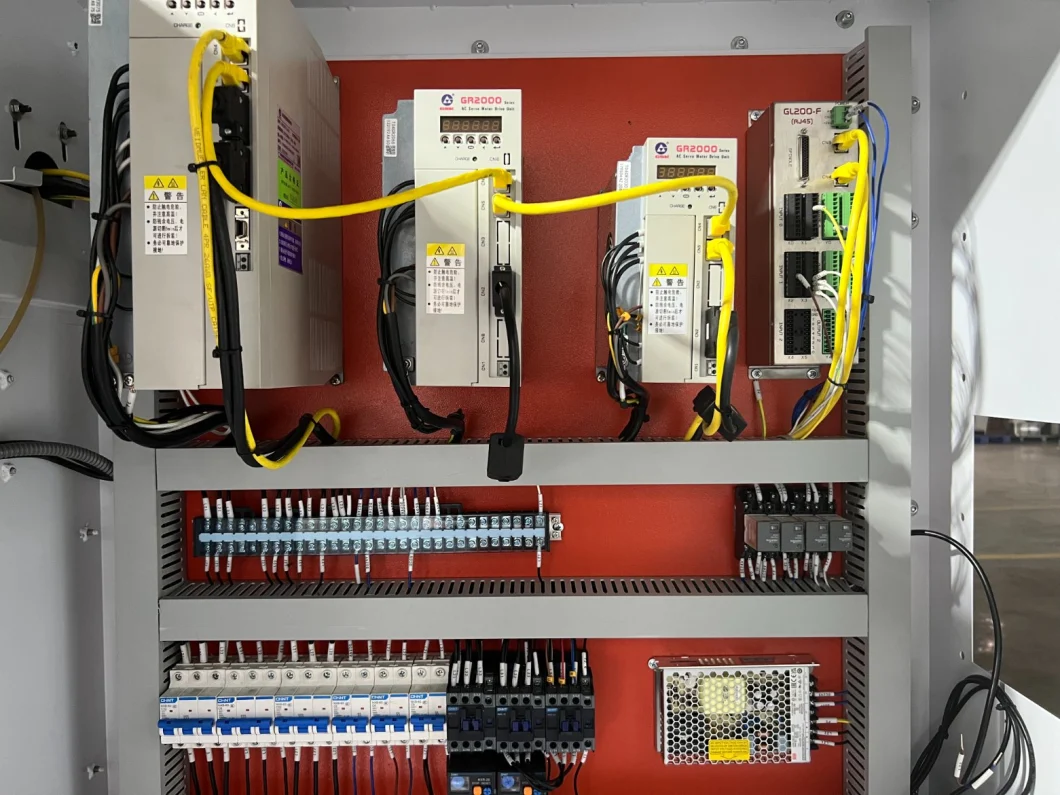

| X Axis servo motor torque | Nm | 6 | |

| Z Axis servo motor torque | 750-1500 | Nm | 10 |

| 2000 | Nm | 15 | |

| Spindle Speed Range(Manual) | Low speed | rpm | 16-160 |

| Medium speed | rpm | 120-600 | |

| High speed | rpm | 400-2000 | |

| Low speed | rpm | 12-100 | |

| Medium speed | rpm | 70-300 | |

| High speed | rpm | 260-1200 | |

| Form of spindle nose | type | C-6 | |

| D-8 | |||

| D-11 | |||

| Hole through spindle diameter | mm | φ52 | |

| φ82 | |||

| φ 105 | |||

| Manual three-jaw chuck | mm | φ250 | |

| Spindle motor power | kw | 7.5Kw Servo 7.5kw | |

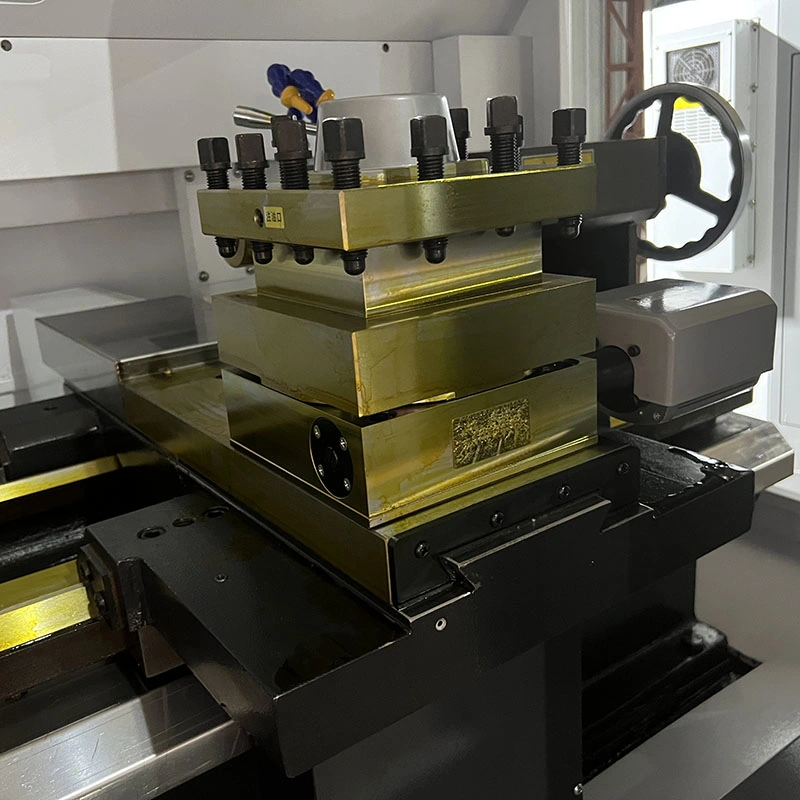

| Electric tool holder form | type | Four vertical stations | |

| Cutting tool specifications | mm | 25×25/φ32 | |

| Tail seat sleeve diameter | mm | φ75 | |

| Taper of tail seat sleeve hole | mm | MT5# | |

| Dimensions | 1000 | mm | 2625×1414×18152600KG |

| mm | |||

| mm | |||

In the future, Lizhun will continue to maintain the spirit of innovation and excellence to provide strong and lasting support for the processing industry, and provide excellent processing machines for 5G, aviation, automobile and other industries.Lizhun Machinery is located in Dongguan, Guangdong province. The product exhibition hall is located in Songshan Lake, Dongguan City, with beautiful scenery and elegant working environment. The factory is located in Dalingshan, with complete facilities and experienced staff. The staff has many years of experience in innovation, development, assembly and production, which ensures that each machine has extremely outstanding quality and performance when it leaves the factory.The factory covers a large area and has multiple production lines to ensure production capacity and supply capacity. Excellent capacity and supply capacity can ensure that customers can receive the machine within the agreed time which can avoid a series of problems caused by insufficient capacity.FAQ

1. Is it all right to make customer's own brand name?

A: yes. we are available with OEM

2. Are you a manufactuer or trading company?

A:We are the manufacturer

3. Can you do the design for us?

A: yes. if you want a different control system design or higher column , we are available.

4 . What is your terms of delivery?

A: FOB shenzhen.

5. What's your payment term?

A: T/T OR L/C at sight.