Robot Polishing Machine/Polishing Machine/Lapping Machine/Grinding and Polishing Machine

General Introduction: The small tool machining machine based on industrial robot uses the small tool to rotate on the su

Basic Info

| Model NO. | RAY-XS128# |

| After-sales Service | 3r Quality Warranty |

| Warranty | 12 Months |

| Transport Package | Custom as Per Demand |

| Specification | custom as per demand |

| Trademark | Raytek |

| Origin | China |

| HS Code | 8464201000 |

| Production Capacity | 100unit Per Year |

Product Description

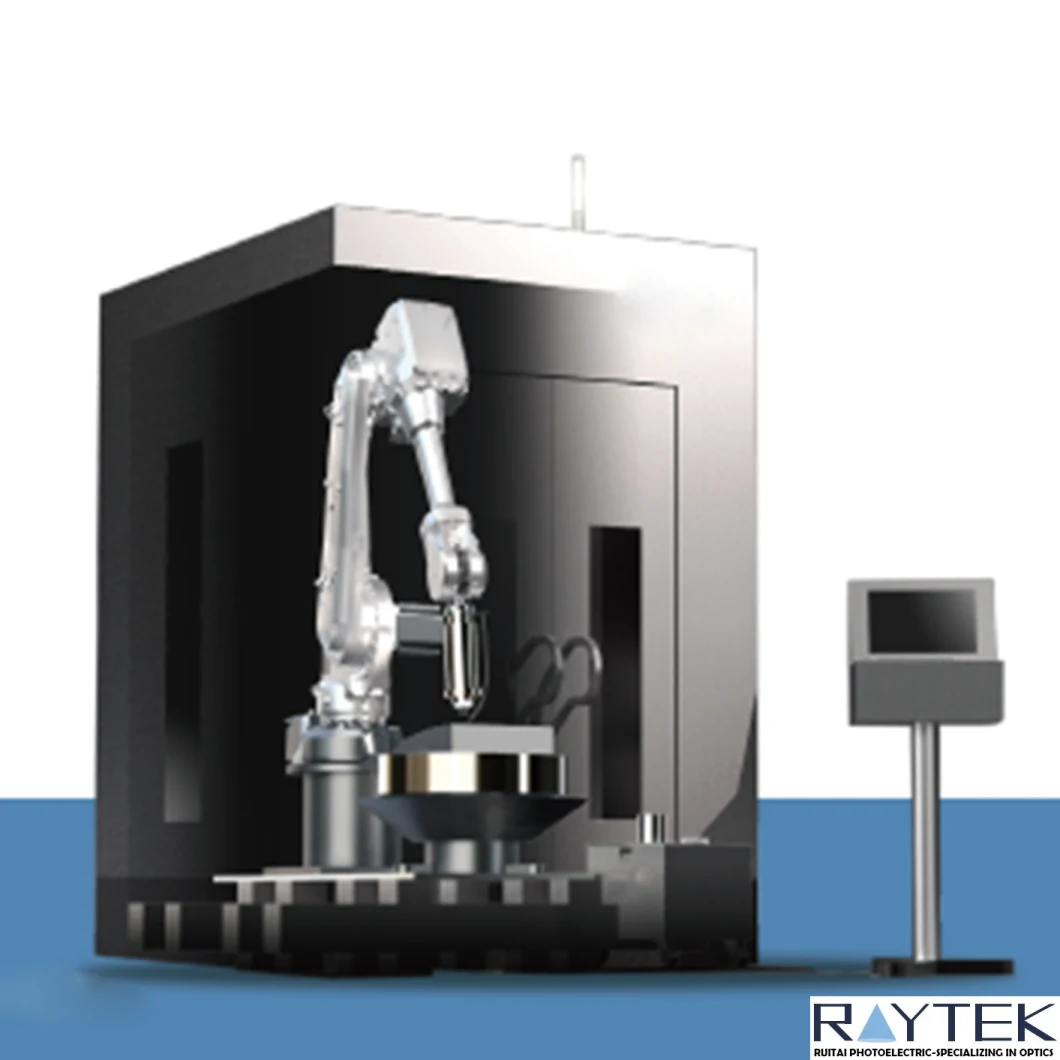

General Introduction:The small tool machining machine based on industrial robot uses the small tool to rotate on the surface of components at high speed to realize the rapid convergence of the surface shape of planar, spherical and aspheric components.

The self-developed flexible polishing head based on the force control sensor ensures that the material removal function is stable and controllable in the polishing process, so as to realize the high-precision machining of the surface of ultra-precision components. With the full-link process and software, the full-link processing from grinding to precision polishing of optical components can be realized.

Products Keywords:

Robot polishing machine/polishing machine/Lapping Machine/grinding and polishing machine

Features:

1. Based on the special control system of industrial robots, high precision surface molding is realized.

2. The design of flexible polishing head based on force control sensor can precisely control the removal function of machining process.

3. Developed open, full-link processing software according to processing requirements.

4. Customized development according to customer requirements.

Applications:

High precision machining of planar, spherical and aspherical components.

Product Specifications:

| Item | Parameter |

| Machinable material | Fused silica, K9, microcrystalline and other optical elements, alloy aluminum and other metal elements |

| Max machined size | Ø2000mm |

| Speed of polishing tool | 50-800 RPM |

| Force sensor range | Fx/Fy:100N; Fz:200N |

| Force sensor accuracy | Nonlinearity and trailing is better than 0.5%, crosstalk is better than 2% |

| Force sensor resolution | Fx/Fy: 0.09N; Fz: 0.33N |

| Range of motion of tool shaft | 1: ±180 2: -90° to +150° 3: -180° to +75° 4: -400° to +400° 5: -125° to +120° 6: -400° to +400° |

| Max speed of tool shaft | Axes 1-6 are 175°/s |

| Repeated positioning accuracy | 0.06 mm |

| Demand for area | 3.5mx3.5mx3m |

| Temperature requirements | 22±0.5ºC |

| Humidity requirements | 40%-80%RH |

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products with "3R" policy. For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.

Send to us