Precision Automatic Hardware Lapping and Polishing Machine

Basic Info

| Model NO. | KS700Y |

| Certification | ISO 9001, SGS |

| Condition | New |

| Max. Grinding Diameter | 200mm |

| Model Number | Ks700y |

| Voltage | 380V |

| Power | 13.6kw |

| Weight | 2800kg |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Transport Package | Standard Export Packing |

| Specification | 1450*1750*2350mm |

| Trademark | Kizi |

| Origin | China |

Product Description

DescriptionKIZI provides the most efficient and reliable solutions for flat lapping and polishing of components utilized in medical,mechanical seals, ceramic,automotive optical,photonic,MEMS,wafer and compound semi-conductor applications and other industrial markets.Products Show

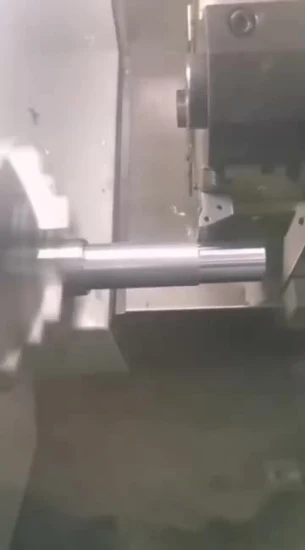

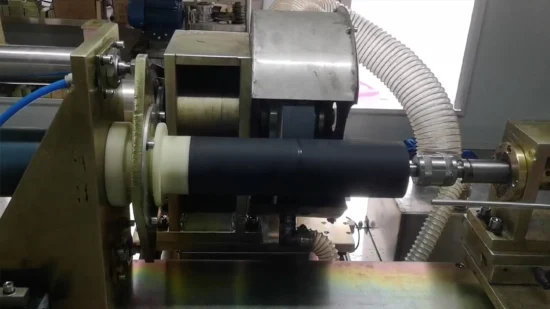

KS700Y Precise Lapping Machine

Usage: Major in precise lapping valve plate, valve piece, friction plate, rigidity seal ring, qir cylinder piston ring, oil pump vane etc precision hardware or metal and non-metal hard material's dual-plane lapping.

Features:

1. Use Swedish "ABB",PLC program control system, to make sure the stability and safety of machine;2. Use Japanese "NSK"/ German "FAG" high precise high speed shaft system; Effectively ensure the working accuracy when high speed, high strength lapping;3. Intelligentialized automatic thickness detection system, the best accuracy of resolution is up to 0.001um. Make sure mass production item thickness size tolerance have stable TTV;4. Upper plate rocker arm device with matching feeding working table improved the Pick & Place convenience;5. Upper plate automatic protection device, prevent accident like fall plate caused by unexpected expired and power failure;6. Use independent inverter motor drive, make the upper plate, lower plate, center wheel and the speed reach the best ratio, and make the loose pully realize clockwise rotation and iversion, and satisfy each machining and fixplate artwork requirement;7. Use Japanese "SMC" pneumatic element matching stepless mutistage precise pressing control system, suitable for coarse lapping, middle lapping, precise lapping, polish ect artwork requirement;8. To meet different material machining requirement, develop customize adamas lapping plate with different formula;9. Precise magnetism and paper tape filtration system.

Our Service

1. Factory with competative price,high quality and stability 2. R&D Dep. with 20 technicians, 5 of them in decades experience 3. Free charge of customer sample making 4. Completed After sales service and expertise support from Taiwan

Our Company

Workshop & LabCompany ActivityPatent

Packing & Delivery

Packing Details : Packing, 1 pcs/cartonDelivery Details : Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity

FAQ

Q: Are you trading company or manufacturer ?

A: We are manufacturer.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A:No, we could not offer the machine sample for free charge but can provide free proofing for the customer.