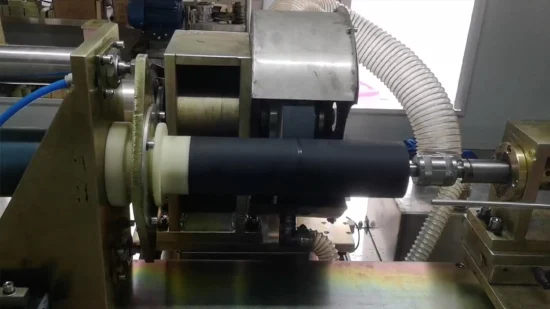

Optical Glass Grinding Lapping Polishing Finishing Surface Machine From China Factory

Overview SGA3063AH Saddle Moving Surface Grinder Product Description Structural Features --Cross board layout--High prec

Basic Info

| Model NO. | SGA3063AH |

| Automatic Grade | Semiautomatic |

| Cylindrical Grinder Type | End Cylindrical Grinder |

| Precision | High Precision |

| Certification | CE, ISO 9001, SGS |

| Condition | New |

| Table Size | 305X635mm |

| Max.Longitudinal Travel | 765mm |

| Cross Tranal | 340mm |

| Max.Distance From Spindle Center Totable | 580mm |

| Magnetic Chuck Size | 300X600mm |

| Speed of Table Longitudinal Movement | 7-23 |

| Auto Feed | 0.1-8mm/Min |

| Rapid Speed | 990mm/Min |

| Feed of Handwheel | 0.02mm/Div |

| Grinding Wheel Speed | 1450rpm, 1750rpm |

| Grinding Wheel Size | 350X40X127mm |

| Spindle Motor | 5.5kw |

| Hydranlic Motor | 2.2kw |

| Cooling Pump Motor | 0.125kw |

| Max. Loading Capacity of Table | 270kg |

| Transport Package | Plywood Packaging |

| Trademark | OEM |

| Origin | China |

| HS Code | 8460291100 |

| Production Capacity | 2000unit/Year |

Product Description

SGA3063AH Saddle Moving Surface GrinderProduct Description

Structural Features--Cross board layout--High precision sliding screw--High strength cast iron foundation

The machine adopts the cross plate layout, and the transverse guide rail is attached with teflon foft belt. Closed hydraulic system is adopted for the movement of the worktable. The forward and backward feed can be manually fed or the screw can be driven by the motor to automatically feed intermittently. The downward movement of the grinding head can be achieved by using the lifting motor for quick lifting(AHR) or the servo motor for quick lifting and automatic feeding(AHD), which can also be accomplished manually. The machine adopts precise angular contact rolling bearing, high rigid sleeve structure, the overall quality of the machine is stable, smooth operation.

Product Parameters

Description | Unit | SGA-3063AH | SGA-4080AH | |

| SGA-3063AHR | SGA-4080AHR | |||

| SGA-3063AHD | SGA-4080AHD | |||

| Table size (w*L) | mm | 305x635 | 406x813 | |

| Max.longitudinal travel | mm | 765 | 910 | |

| Cross travel | mm | 340 | 450 | |

| Max.distance from spindle center to table | mm | 580 | 580 | |

| Magnetic chuck size | mm | 300x600 | 400x800 | |

| Speed of table longitudinal movement | m/min | 7-23 | 7-23 | |

| Table transverse movement | Auto feed | mm/min | 0.1-8 | 0.1-8 |

| Rapid speed | mm/min | 990 | 990 | |

| Feed of handwheel | mm/div. | 0.02 | 0.02 | |

| Wheelhead vertical movement | Auto feed | mm/stroke | 0.005/.001/0.02/0.03/0.04/0.05(only for AHD model) | |

| Rapid speed | mm/min | 460 (only for AHR/AHD model) | ||

| Feed of handwheel | mm/div. | 0.005 | ||

| Grinding wheel | Speed | rpm | 1450(50hz);1750(60hz) | 1450(50hz);1750(60hz) |

| Size (OD*W*ID) | mm | 350x40x127 | 350x40x127 | |

| Spindle Motor | kw | 5.5 | 5.5 | |

| Hydralic motor | kw | 2.2 | 2.2 | |

| Cooling pump motor | kw | 0.125 | 0.125 | |

| Elevating motor | kw | -------(AH mode) 0.25(AHR mode)0.5 (AHD mode, servo motor) | ||

| Cross feed motor | kw | 0.04 | 0.04 | |

| Max.loading capacity of table(include magnetic chuck) | kg | 270 | 500 | |

| Total rated power | kw | 9 | 9 | |

| Height of machine | mm | 1890 | 1890 | |

| Floor space (L*W) | mm | 2900x2200 | 3600x2400 | |

| Gross weight | kg | 2600 | 3500 | |

| Package dimension (LxWxH) | mm | 2350x2220x2150 | 2850x2270x2180 | |

Hot ProductsCompany Profile

Send to us