Heavy Duty Screw Drive High Precision Fanuc Siemens Horizontal CNC Mill Drill Machine for Metal Box Parts

Basic Info

| Model NO. | PW-CNC1160 |

| Performance Classification | High-End CNC Machine Tools |

| Certification | CE, ISO 9001 |

| Condition | New |

| Operation System | Siemens |

| Protection Cover | Fully Enclosed |

| Spindle Tapper | Bt40 |

| Spindle Installation | Horizontal |

| Maximun Speed | 20000rpm |

| Cooling System | Water Cooling |

| Max Torque | 35/42 N.M |

| Spindle of Driven Motor | 7.5 Kw |

| Tool Change Time | 2 Sec. |

| Weight | 10t |

| Transport Package | 40hq |

| Specification | 2550*3650*2500mm |

| Trademark | PRATIC |

| Origin | China(Mainland) |

| HS Code | 8457102000 |

| Production Capacity | 1000 Sets /Year |

Product Description

Description

1. This machine is an automatic machining center integrated with the functions of milling, boring, drilling, reaming and tapping;

2. This machine is a horizontal machining center, and the headstock adopts fixed-distance structure;3. Double working-zone horizontal flip-over type of clamping is available;

4. Application: conference machine, education machine frame; Long aluminum alloy building formwork; Long spliced battery pack, etc.

Advantage

1. The horizontal machining center adopt Headstock Fixed-distance Structure, enhance the machine rigidity.

2. One machine is equivalent to a traditional production line, and the floor area is far less than traditional production line;

3. Clamp two workpieces at a time to complete 6 sides processing, improve collaborative accuracy and reduce positioning error;

4. Worker can clamp the workpiece in the other side when machine processing, improve the production efficiency;

5. The impact of spindle water outlet makes the chips fall directly, reduce the chip accumulation of the fixture and product clamping damage.

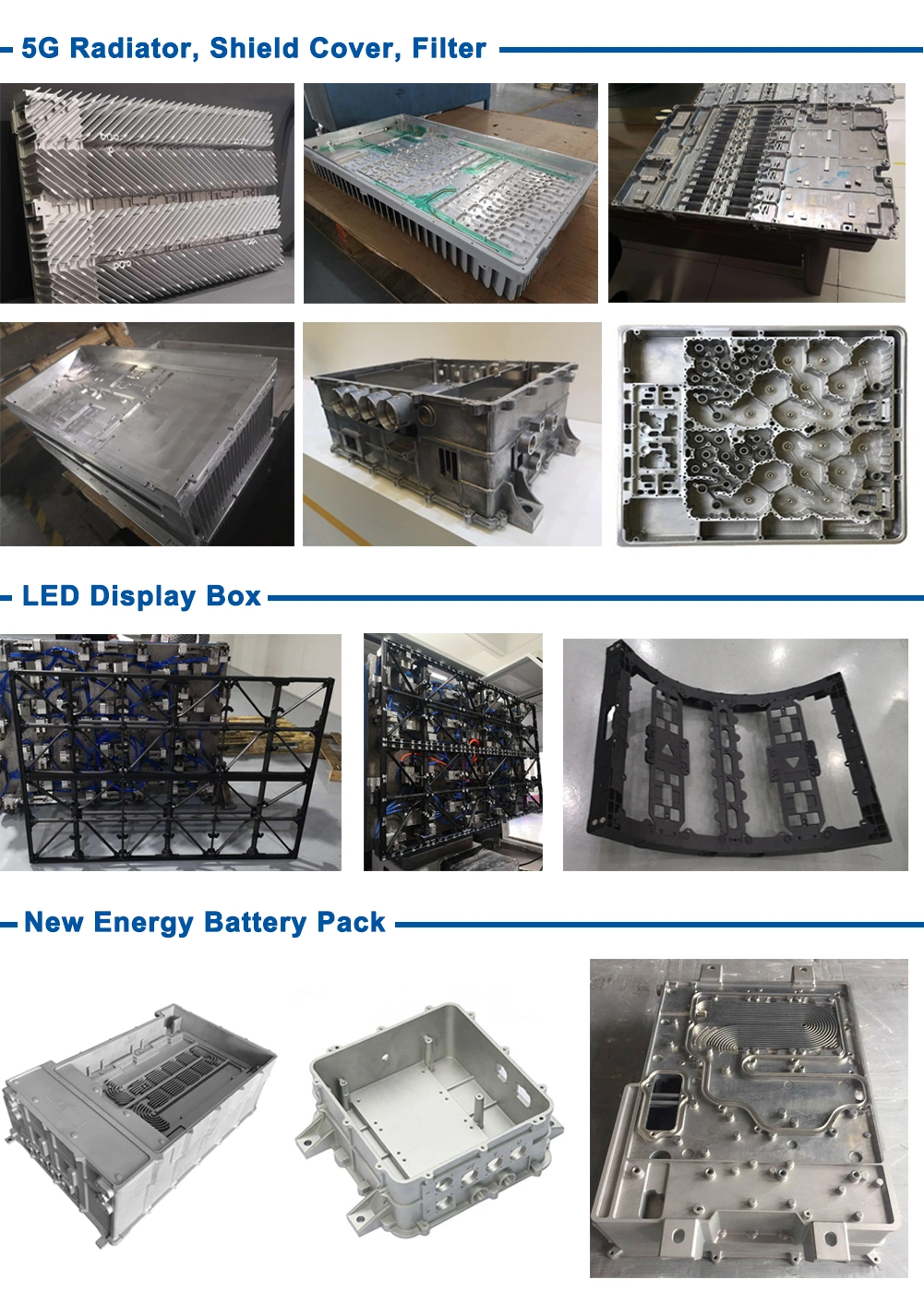

The PWA horizontal machine widely used in processing workpieces such as LED display screen box, 5G communication (including transmitting antenna, filter, radiator, shield cover and various cavity parts), new energy inverter, controller, battery pack, bicycle & motorcycle shell, medical parts and many other capabilities.

Technical Data

| ITEM | SPECIFICATION | |

| X-Axis Travel | 1500mm | 2000mm |

| Y-Axis Travel | 600/800/1100/1300mm | 600/800/1100/1300/1600mm |

| Z-Axis Travel | 400/500/600/650mm | 400/500/600/650/800mm |

| Spindle Taper | BT40 | BT40 |

| Spindle Speed | 20000rpm | 20000rpm |

| Tool Magazine | 32pcs Disc-type | 32pcs Disc-type |

| Tool Change Time | 1.5 sec | 1.5 sec. |

| X/Y/Z Axis Moving Speed | 48 m/min | 48 m/min |

| Position Precision of X/Y/Z Axis | 0.01 /0.01 /0.01 mm | 0.01 /0.01 /0.01 mm |

| Repeating Position Precision of X/Y/Z Axis | ±0.005/300mm | ±0.005/300mm |

| Lubricating System | Automatic Lubricating | Automatic Lubricating |

| Cooling System | Water Cooling | Water Cooling |

| Operation System | SIEMENS | SIEMENS |

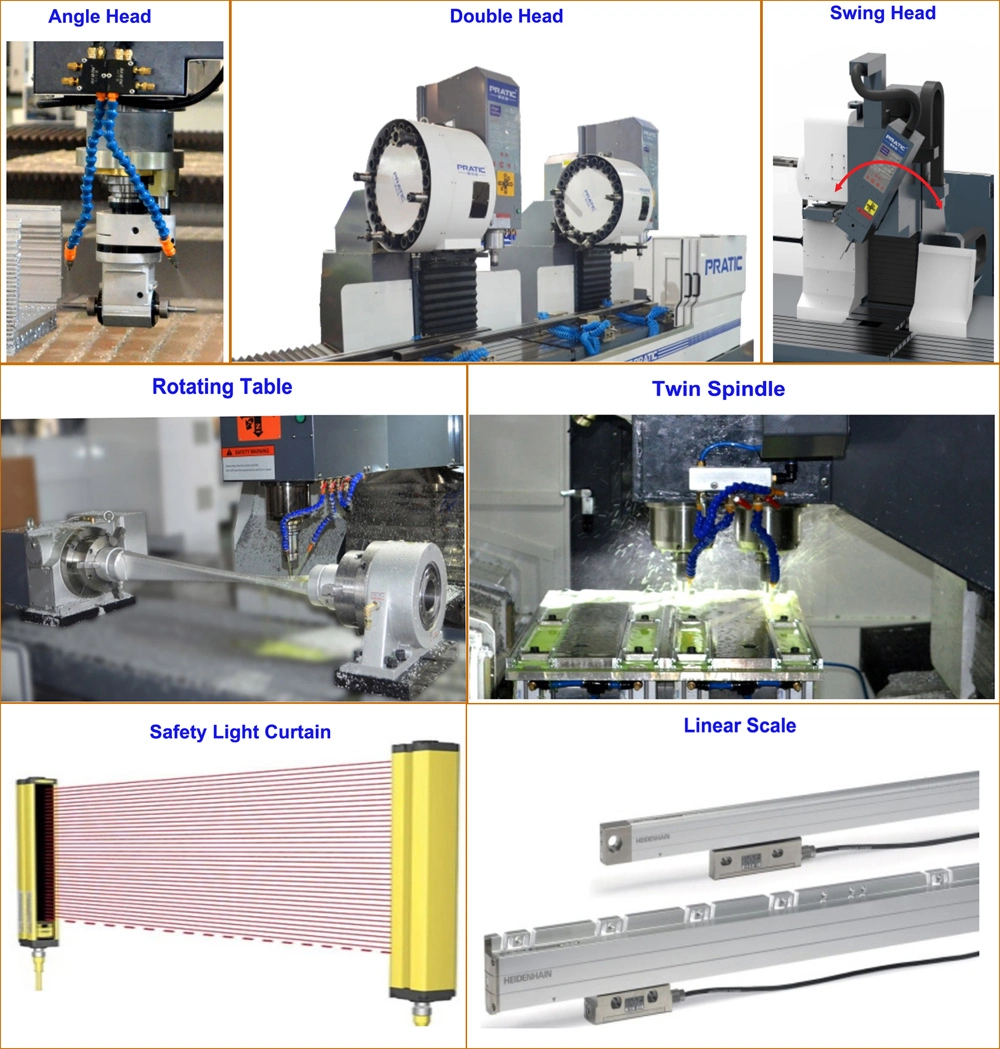

Option Feature

About PRATIC

PRATIC CNC Technology is a reputable manufacturer from China that specializes in CNC machining center and automatic machinery. Our products cover a wide range of CNC machining centers for an effective metal machining. Diverse materials from aluminum,steel, composites to plastics can be machined precisely, productively and economically on the milling machines from PRATIC.

Company Strength

1) R&D Team & International StandardsPRATIC owns a design & research team of more than 30 people. PRATIC continuously challenges the technology difficulties, break the limitation of the industry, and carry out deep cooperation with the companies from Germany, Japan, South Korea and Singapore.PRATIC operates according to a strict quality system and PRATIC has got the international ISO9001 qualification, and PRATIC machining centers are produced by the international standards, and all the moldes of PRATIC machining centers have got CE certificates.2) Lean Management & After-sale ServicePRATIC carries out 5s management, visible management and demand-oriented management to ensure the effectiveness and efficiency in production and daily operation.PRATIC offers Free Installing, Free Training, Timely Delivery and Reassuring After-sale Service. Your questions will be answered and your problem will be solved in quickest time! In some countries we have local agents who will offer you the best local after-sale service and maintenance!

3) Quality Assurance: PRATIC enforces the strictest inspections and tests to its each machining center as well as components & workpieces.Inspections & Tests: Flatness Inspection, Parallelism Inspection, Position Precision Inspection, Repeating Position Precision Inspection, Three-Coordinate Inspection, Long-Time Run Test...All the inspections and tests are carried out to ensure each machining center is in 100% perfect condition when delivered to customers!

FAQ

Q1: I knew nothing about this machine, what kind of machine i should choose? Very easy to choose. Just tell us what you want to do by using CNC machining center, then let us give you perfect solutions and suggestions.Q2: When I got this machine, but I don't know how to use it. What should I do? We will send video and English manual with the machine. If you still have some doubts, we can talk by telephone or skype and e-mail.

Q3: If some problems happen to this machine during warranty period, what should I do? We will supply free parts during machine warranty period if machine have some problems. While we also supply free life long after-sales service. So any doubts, just let us know, we will give you solutions. Q4: Before sending me an inquiry on our machine, it is better for you to provide me the following information1)Your metal workpiece size. Because in our factory, we have different models according to working area.2)Your workpiece materials.Aluminum/Steel/Iron/Titanium Alloy?3) You also can send us the drawing of your workpiece, so that we can have a moe careful check and give your more accurate suggestions.

Participation in International Exhibitions

PRATIC Agents Wanted