Glass-Ceramic Ultra-Thin Double-Sided Lapping and Polishing Machine 722

Basic Info

| Model NO. | KS25D |

| After-sales Service | Provide Overseas After-Sales Service |

| Warranty | Provide Overseas After-Sales Service |

| Type | Surface Grinding Machine |

| Processing Object | Metal&Nonmetal |

| Abrasives | Grinding Disc |

| Controlling Mode | Normal |

| Automatic Grade | Semiautomatic |

| Cylindrical Grinder Type | Surface Grinder |

| Precision | High Precision |

| Certification | ISO 9001 |

| Condition | New |

| Max. Grinding Diameter | 202mm |

| Model Number | Ks25D |

| Voltage | 380V |

| Power | 6.5kw |

| Weight | 1750kg |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Transport Package | Standard Export Packing |

| Specification | 1680*1160*2350mm |

| Trademark | Kizi |

| Origin | China |

| Production Capacity | 10/ Month |

Product Description

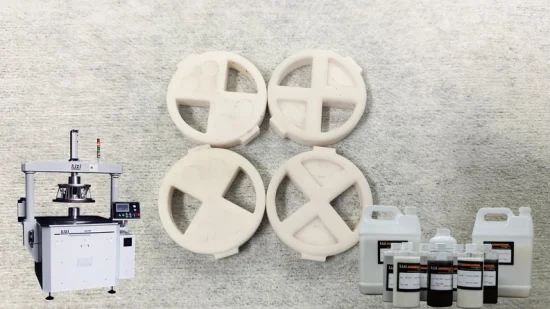

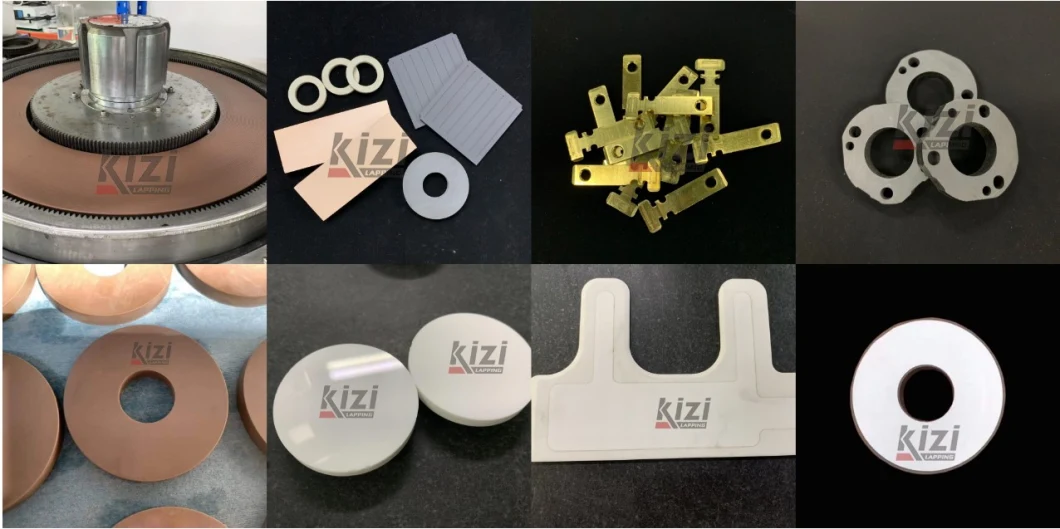

DescriptionKIZI provides the most efficient and reliable solutions for flat lapping and polishing of components utilized in medical, mechanical seals, ceramic, automotive optical, photonics, MEMS, wafer, and compound semi-conductor applications and other industrial markets.Products Show

Series B double-sided lapping and polishing machine

Usage: This series machine is designed and produced for double-sided lapping and polishing all kinds of seals, alumina, zirconia ceramic, glass, metal components, semiconductor components ect metal, and non-metal product.

Equipment Highlights

Diamond precision grinding discs that challenge extreme processingAutomatic floating positioning device of the upper plate

The unique automatic floating positioning device of the upper plate reduces the trouble of wrong and right plates.

The whole machine is operated with independent motor dragging

The whole machine is driven by independent motors, so that the upper and lower plates, the central wheel and the speed can be optimally proportioned.

Features:

1.Man-machine interface program control system, ensure the machine stability, security

2.Segmentationprecision pressure control, suitable for coarse, medium and fine grinding and polishing process

3.Using high precision shaft system, to ensure the precision of machine tools and durability

4.Unique safety lock merchanism, to prevent accidental expired, power failure and disk fall hurt accident

5.Outer ring gear and water retaining plate of semi-automatic ifting system, convenient to leave work pieces

6.The machine running using the independent motor, make the upper and lower plate and the center of the gear peed to achieve the optimal proportion, cruise ships to achieve positive & negative, meet the repair disk process requirement

Our Service

1. Factory with competitive price, high quality, and stability 2. R&D Dep. with 20 technicians, 5 of them in decades of experience 3. Free charge for customer sample making 4. Completed After sales service and expert support from Taiwan

Our Company

Dongguan Kizi Precision Grinding Machinery Manufacturing is an affiliated company of Fushan Industrial Group, which mainly develops, manufactures and sells high precision surface grinding machines, precision surface polishing machines and other CNC equipments and their supporting consumables. Our products are widely used in metal, non-metal (including ceramics, sapphire) parts grinding and polishing process, the workpiece can obtain the best 0.2um flatness and 0.02um roughness.

Kizi's mission is "to provide the best grinding and polishing solutions for our partners", and with more than 20 years of rich grinding and polishing technology from Taiwan, kizi's R&D team has been constantly making technical innovations, breaking through the technical difficulties of new projects such as sapphire and ceramic grinding and polishing, and obtaining many patents. The matching grinding powder and grinding liquid all meet the environmental protection requirements and obtain SGS certificate; the company successfully introduced ISO9001 quality certification system to ensure that all product quality is in line with the standards.

Workshop & LabCompany ActivityPatent

Packing & Delivery

Packing Details : Packing, 1 pcs/cartonDelivery Details : Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity

FAQ

Q: Are you trading company or manufacturer ?

A: We are manufacturer.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A:No, we could not offer the machine sample for free charge but can provide free proofing for the customer.