Alumina Ceramic Lapping and Polishing Machine

Why Ponda? Ponda has profound experience of lapping, polishing and thinning. We heretofore supplied more than 60, 000 la

Basic Info

| Model NO. | FD9103LX |

| Variable Speed | With Variable Speed |

| Service | Oversea Setup & After-Sale Avalaible |

| Class | Single Plate |

| Process Station | 3 |

| Pressure Source | Pneumatic or Weight Block |

| Plate Material | Metal & Non-Metal |

| Abrasive | Slurry |

| Weight | 1000kg |

| Transport Package | Wood Crate |

| Trademark | PONDA |

| Origin | China |

| Production Capacity | 500 Unit/Year |

Product Description

Why Ponda?Ponda has profound experience of lapping, polishing and thinning. We heretofore supplied more than 60, 000 lapping process solutions and appliances over the industries of machinery, electronic, aerospace, aviation, automotive, atomic energy, optics; the substances of metal, SiC wafer, ceramics, glass, industrial sapphire, plastics, and any other composites.

Main uses:

The mirror polishing machine is suitable for high-precision single plane grinding and polishing of large workpiece and batch production of small workpiece. Such as: aluminum alloy, light plate stainless steel, tungsten steel, aluminum, alloy and other metal material products

Products Show

Working principle:

1. The polishing equipment is a precision grinding and polishing equipment. The grinding and polishing materials are placed on the grinding disc, which rotates against the clock.2. The dressing mechanism of the grinding disc adopts the hydraulic suspension guide rail to move back and forth, and the diamond trimming knife trims the grinding surface of the grinding disc precisely to obtain the ideal plane effect.

Special points:

1. The pressure of series mirror polishing machine parts is cylinder pressure, the pressure is adjustable;2. Series of mirror polishing machine using PLC program control system, touch screen operation panel, grinding disk speed and timing can be directly input on the touch screen.

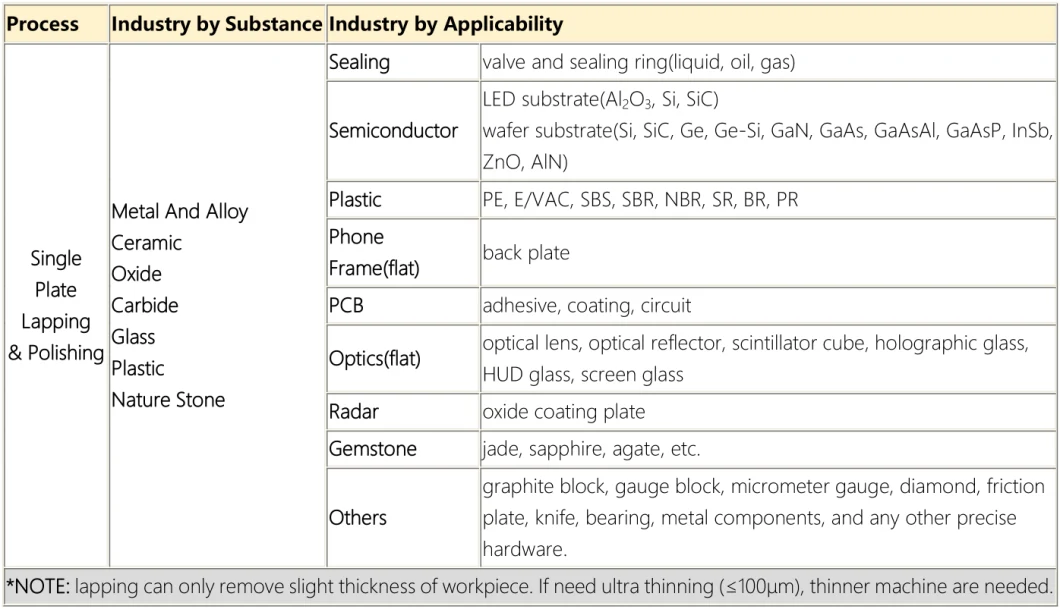

APPLICATION

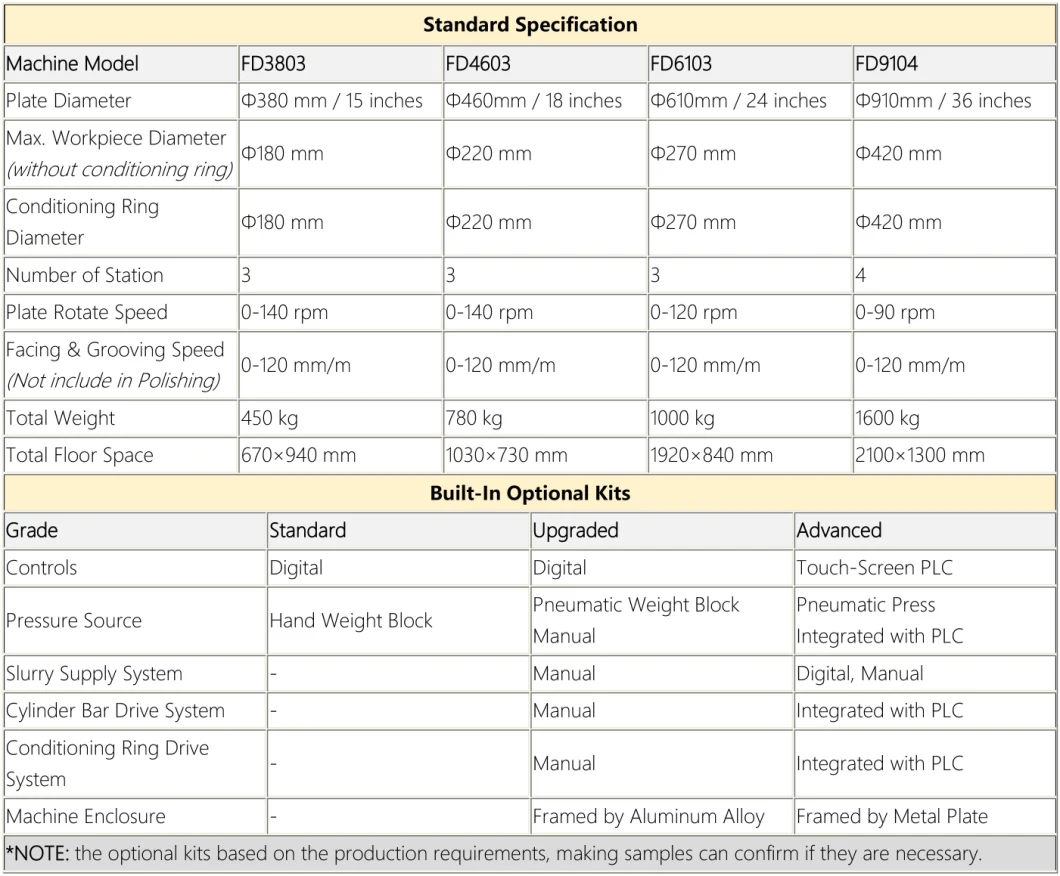

SPECIFICATION

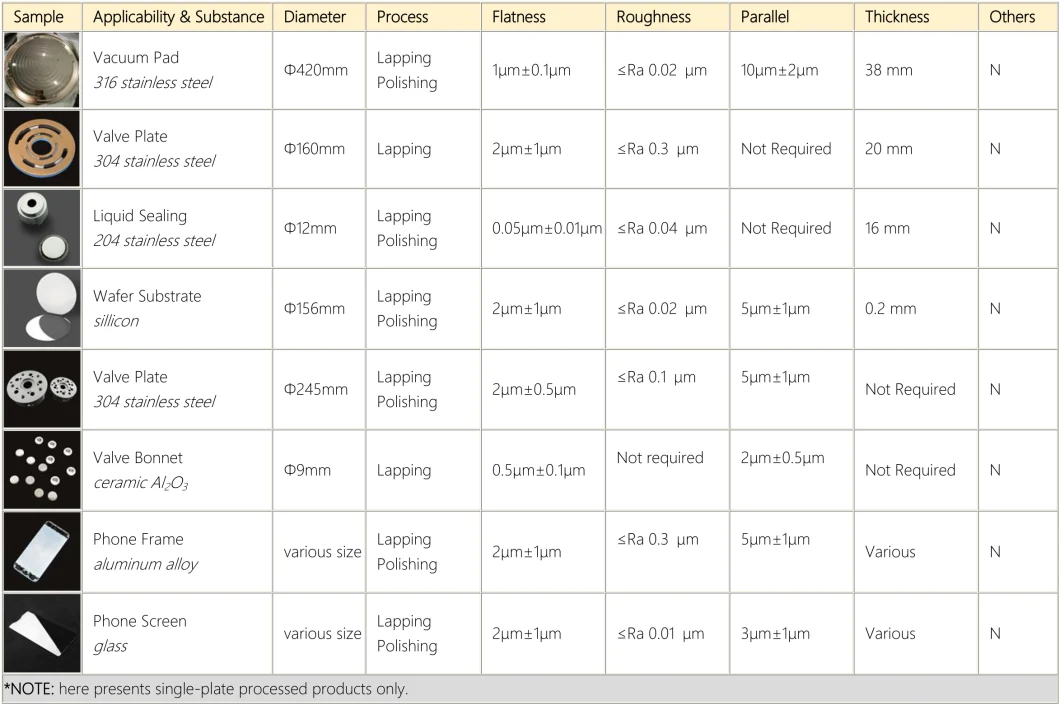

SAMPLE DEMONSTRATION (SINGLE PLATE)

About the Company

Factory front desk

Ponda is a high-tech enterprise specializing in all kinds of high precision grinding equipment, polishing equipment and itssupporting products and consumable materials

Patent

FAQs

Q1: Which machine is most applicable for my product?

A: It usually depends on 5 requirements and parameters of your product: flatness, roughness, thickness, dimension, productivity:1. If better flatness and roughness were required, you might need both lapping and polishing machine.2. If to thin the product in a big margin, such as 500μm, you might need a thinner machine for extra.3. If the productivity were excessive, you might need larger machine or to expand production line.Additionally, we can confirm the production line as we make samples for you.Q2: Does Ponda charge for making samples?

A: No, it's free to make samples.

Q3: Is Ponda trader or manufacturer?

A: We are manufacturer, certified National High-Tech Enterprise.Q4: How long does it take machine to deliver?

A: Approximately 15 days to deliver. If the machine are out of stock, we need 15 days more to manufacture.Q5: Does Ponda provide oversea setup and after-sale service?

A: Yes, we provide oversea service and online tutorial.Q6: How many type of machine does Ponda manufacture?

A: We have 21 major series of machines, 5 different types run in different principles, more than 15 types of plates, 100 types of slurries.

Send to us