Horizontal Bead Mill for Paint, Ink, Pigment, Agrochemical

Basic Info

| Model NO. | ZM&ZM-X&ZM-E |

| Type | Disc Grinder |

| Applicable | Chemical and Medicine |

| Object | Milling Cutter |

| Suitable Grinding Medium | Zirconium/Zirconia/Zircon Beads |

| Function | Wet Grinding for Particle Size Reduce |

| Bead Mill Type | Disc Type, Turbo Type, Pin Type |

| Ex Proof Type | Ex Proof and Non Ex Proof |

| Cooling Water Jacket | Yes |

| Warranty | 12 Months |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Transport Package | Fumigation Free Wooden Box |

| Specification | CE, ISO9001: 2008, SGS |

| Trademark | DEGOLD |

| Origin | Chongqing, China |

| HS Code | 847982 |

| Production Capacity | 600sets/Year |

Product Description

Degold ZM seires bead mills are suitable for continuous wet grinding of solids in liquid materials, and they are widely used in paint, coating, ink, pigment, color paste, cosmetic, pesticide, non-metal mines industries.

There are various models such as 0.3L, 1.4L, 5L, 15L, 20L, 30L, 50L, 60L, 100L, 200L, 250L etc. different volumes disc grinder.Except disc grinder, Degold also produces pin type horizontal bead mill and turbo type horizontal bead mill.

| "Series ZM" horizontal bead mills: | grinding discs type bead mills |

| "Series ZM-X" horizontal bead mills: | |

| "Series ZM-E" horizontal bead mills: | |

| "Series ZM-K" horizontal bead mills: | pin type bead mills |

| "Series ZM-T" horizontal bead mills: | turbo type bead mills |

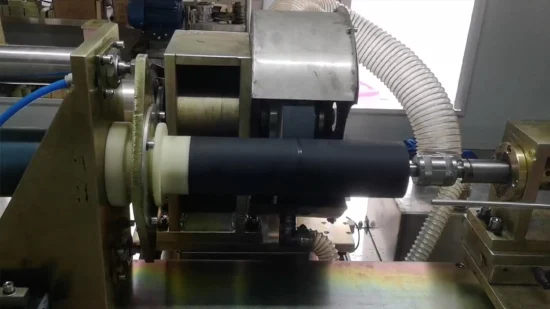

Principle of Operation: The rotary grinding shaft drives all grinding mediums inside the grinding chamber. The grinding mediums passes the powers to the materials to reduce the particle size. Gap separator inside the horizontal bead mills separates the products and the grinding mediums. They are suitable for different viscosities formulations.Different materials inside the horizontal bead mills can be choosen, such as SS304, hard alloy, mold steel, polyurethane, tungsten carbide, ceramic etc.

Applications:

Technical Data:

ZM Series:

| ZM0.3 | ZM1.4 | ZM5 | ZM15 | ZM20 | ZM30 | ZM50 | ||

| Effective grinding chamber volume (L) | 0.3 | 1.4 | 5 | 15 | 20 | 30 | 50 | |

| Main motor power (kW) | 0.75 | 2.2 | 7.5 | 15 | 18.5 | 22 | 30 | |

| Grinding shaft rotary speed (r/min) | 0~1500 | 0~2800 | 1650 | 1200 | 1200 | 1120 | 900 | |

| Adjustable range of materials flow (L/min) | 0~1 | 0~2 | 0~2 | 0~10 | 0~10 | 0~60 | ||

| Max. cooling water consumption (t/h) | 0.5 | 1 | 1 | 2 | 2 | 2.5 | ||

| Estimated productivity (kg/h) | 2~20 | 12~120 | 30~300 | 40~400 | 50~600 | 100~1000 | ||

| Dimension (mm) | L | 640 | 650 | 1250 | 1560 | 1600 | 1860 | 2100 |

| W | 410 | 570 | 900 | 1050 | 1050 | 1100 | 1150 | |

| H | 485 | 885 | 1250 | 1550 | 1550 | 1550 | 1650 | |

| Net weight (kg) | 50 | 500 | 700 | 800 | 980 | 1100 | 1300 | |

| Note: Technical data are different if there are some customized constructions. | ||||||||

ZM-X Series:

Model | ZM5-X | ZM15-X | ZM20-X | ZM30-X | ZM50-X | ZM100-X | ZM200-X | |

Effective grinding chamber volume (L) | 5 | 15 | 20 | 30 | 50 | 100 | 200 | |

| Main motor power (kW) | 11 | 18.5 | 22 | 30 | 37/45 | 45/55 | 55/75 | |

| Grinding shaft rotary speed (r/min) | 1650 | 1200 | 1200 | 1120 | 900 | 700 | 550 | |

| Adjustable range of materials flow (L/min) | 0~2 | 0~2 | 0~10 | 0~10 | 0~60 | 0~60 | 0~150 | |

| Max. cooling water consumption (t/h) | 1 | 1 | 2 | 2 | 2.5 | 2.5 | 3~4 | |

| Estimated productivity (kg/h) | 15~150 | 40~400 | 50~500 | 60~800 | 150~1500 | 150~1500 | 200~2000 | |

| Dimension (mm) | Length | 1250 | 1560 | 1670 | 1760 | 1970 | 2175 | 2150 |

| Width | 900 | 1050 | 1050 | 1050 | 1150 | 1200 | 1200 | |

| Height | 1250 | 1550 | 1565 | 1585 | 1650 | 1880 | 2150 | |

| Net weight (kg) | 700 | 800 | 1000 | 1150 | 1350 | 2000 | 2500 | |

| Note: Technical data are different if there are some customized constructions. | ||||||||

ZM-E Series:

Type | ZM20-E | ZM50-E | ZM100-E | ZM200-E | ZM300-E | ZM500-E | ZM1000-E |

Grinding chamber volume (l) | 20 | 50 | 100 | 200 | 300 | 500 | 1000 |

Batch size (l) | 100-500 | 200-1000 | 500-2500 | 1000-10000 | >2000 | ||

Drive (kW) | 18.5/22 | 37/45 | 55/75 | 75/90 | 90/110 | 160/200 | 315 |

Grinding shaft rotary speed (r/min) | 1200 | 800 | 650 | 500 | 460 | 350 | 340 |

Length (mm) | 1670 | 1970 | 2750 | 2950 | 3450 | 3350 | 6650 |

Width (mm) | 1050 | 1150 | 1200 | 1200 | 1300 | 1500 | 1450 |

Height (mm) | 1565 | 2000 | 2200 | 2200 | 2250 | 2700 | 2850 |

Net weight (kg) | 750 | 1500 | 3500 | 3700 | 4700 | 8000 | 12000 |

Note: Technical data are different if there are some customized constructions. | |||||||

ZM-K Series:

| Type | ZM10-K | ZM25-K | ZM60-K | ZM150-K |

| Grinding chamber volume (l) | 10 | 25 | 60 | 150 |

| Batch size (l) | 500 | 2000 | >2000 | >4000 |

| Drive (kW) | 18.5-22 | 37-45 | 75-90 | 160-250 |

| Length (mm) | 1670 | 2050 | 2500 | 3000 |

| Extended length (mm) | 2100 | 2700 | 3280 | 4100 |

| Width (mm) | 900 | 1000 | 1195 | 1220 |

| Height (mm) | 1500 | 1600 | 1900 | 2500 |

| Weight (kg) | 1250 | 2250 | 3600 | 6700 |

| Note: Technical data are different if there are some customized constructions. | ||||

ZM-T Series:

| Type | ZM8-T | ZM18-T | ZM25-T | ZM60-T |

| Grinding chamber volume (l) | 8 | 18 | 25 | 60 |

| Batch size (l) | 100-1500 | 300-2500 | 400-3000 | 500-6000 |

| Drive (kW) | 18.5-22 | 37-45 | 45-55 | 75-90 |

| Length (mm) | 1400 | 1800 | 1900 | 2300 |

| Width (mm) | 800 | 1050 | 1050 | 1250 |

| Height (mm) | 1700 | 1900 | 1900 | 2150 |

| Weight (kg) | 900 | 1800 | 2000 | 3600 |

| Note: Technical data are different if there are some customized constructions. | ||||

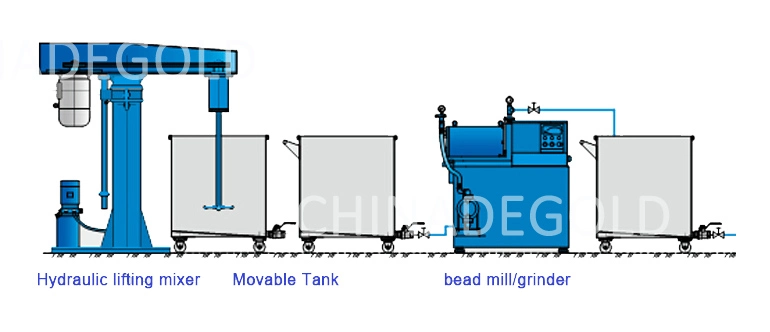

Production Line:

Exhibition:

Bead Mills at Customer's Site:

| Model | Motor (kW) | Grinding Container Volume (L) | Production Capacity | Weight (approx. ) | Dimension (L× W× H)mm |

| ZM0.3 | 0.75 | 0.3 | 50 | 640× 410× 485 | |

| ZM1.4 | 2.2 | 1.4 | 5-50kg/h | 500 | 655× 570× 885 |

| ZM5 | 7.5 | 5 | 20-100 kg/h | 700 | 1250× 900× 1250 |

| ZM15 | 15 | 15 | 30-150 kg/h | 800 | 1560× 1050× 1550 |

| ZM20 | 18.5 | 20 | 50-200 kg/h | 980 | 1600× 1050× 1550 |

| ZM30 | 22 | 30 | 50-300 kg/h | 1100 | 1860× 1100× 1550 |

| ZM50 | 30 | 50 | 60-500 kg/h | 1300 | 2100× 1150× 1650 |

| ZM60 | 30 | 60 | 60-600 kg/h | 1400 | 2100× 1150× 1650 |

| ZM100 | 45 | 100 | 100-1000 kg/h | 2000 | 2250× 1280× 1640 |

| ZM200 | 55 | 200 | 150-1500 kg/h | 2500 | 2250× 1280× 1735 |

| ZM250 | 75 | 250 | 200-2000 kg/h | 2700 | 2800× 1280× 1765 |

| ATTN: Different constructions horizontal bead mills have different technical data. Please contact with seller to get the exact suitable model and technical data. | |||||