Vmc850 -800X500mm High Precision High Speed 3 Axis CNC Metal Vertical Machining Center Milling Machine

Basic Info

| Model NO. | VMC850 |

| Automatic Grade | Automatic |

| Precision | Precision |

| Certification | CE, ISO 9001 |

| Condition | New |

| Floor Space | 2400X2600X2500mm |

| Total Power | 11kw |

| Spindle Speed | 10000rpm |

| Spindle Hole Taper | Bt40 |

| Transport Package | Non-Fumigation Plywood Case |

| Specification | 2400X2600X2500mm |

| Trademark | CD machinery |

| Origin | China |

| HS Code | 8457101000 |

| Production Capacity | 60 Sets/Month |

Product Description

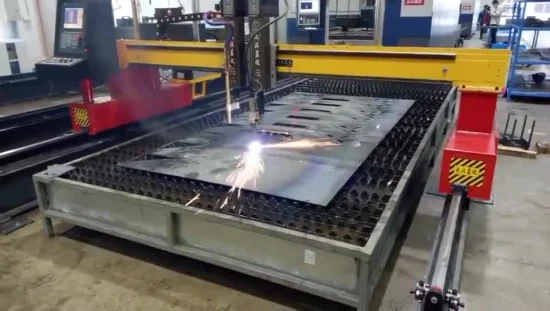

1.Pictures

| Project | Unit | VMC850 |

| Processing range | ||

| X axis | mm | 800 |

| Y axis | mm | 500 |

| Z axis | mm | 500 |

| Distance from spindle center to column guide (mm) | mm | 550 |

| Distance from spindle end to worktable surface (mm) | mm | 150-650 |

| Working table | ||

| Working table size | mm | 500×1000 |

| Max load capacity | kg | 600 |

| T-slot | ||

| T-slot (slot number × slot width × pitch) | mm | 5×18×90 |

| T-slot of working table | 5-18 | |

| Spindle | ||

| Spindle taper (model / installation size) | BT40/φ150 | |

| Spindle speed | rpm | 10000 |

| Automatic tool changer | ||

| Number of tools | Pcs | 24 |

| Tool change time (T-T) | s | 2.5 |

| Three-axis feed | ||

| X / Y / Z axis rapid displacement | m/min | 36/36/30 |

| Cutting feed rate | m/min | 12 |

| Machine accuracy | ||

| Positioning accuracy | mm | 0.008 |

| Repeat positioning accuracy | mm | 0.005 |

| Motor | ||

| Main motor power (FANUC) | KW | 7.5/11 |

| Three-way motor torque | N.m | 12,20,20 |

| CNC system | FANUC 0i-MF | |

| (optional SIEMENS 828D) | ||

| Other | ||

| Machine weight | T | 5 |

| Dimensions | mm | 2400×2600×2500 |

3. Standard Accessories

| 1 | Hand lube pump |

| 2 | Drawbar |

| 3 | Toolbox with tools |

| 4 | Way cover |

| 5 | Operation manual |

| 6 | Simplified electrical box |

| 7 | Work light |

4.Optional Accessories

| 1 | High speed and high rigidity direct coupling spindle |

| 2 | Spindle center water |

| 3 | Chain plate type automatic chip remover |

| 4 | Fourth axis CNC turntable |

5. Machine Features:

The VMC series vertical machining center uses finite element analysis software (Ansys) to optimize the design, which makes the machinestructure design more reasonable, and the machine rigidity, accuracy retention, and reliability are approaching perfection. The machine bed,table, column, milling head, etc. are all made of high-strength cast iron. After secondary tempering and aging treatment, the structure of thereinforcement is optimized to make the machine performance more consistent with the requirements of processing characteristics and stability.

1. The bed rail is designed with large span size, and the column is designed with A-shaped structure, so that the machine has excellent strength,rigidity and thermal stability.

2. High-performance spindle unit imported from Taiwan at 10000rpm, which can be equipped with spindle oil-cooling device to control spindletemperature rise and improve cutting accuracy.

3. The three feed shafts are supported by imported linear roller guides imported from Taiwan to ensure three-axis positioning accuracy.

4. Both ends of the ball screw are pre-stretched, which increases the transmission rigidity and eliminates the thermal deformation generatedduring rapid movement in advance.

5. The machine adopts full protection design of splash-proof sheet metal, beautiful and generous to ensure the personal safety of the operator.

6. Dellivery Picture

7.Company & Factory

Nantong CD Machinery is located in the beautiful city of Nantong, about 100 kilometers away from Shanghai.Our main products are : CNC grinding Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe Machine ,Drilling Machine ,Milling Machine and others metal cutting machine tools .All the products above have passed CE ,ISO certificates . Our company formed a good win-win relationship with domestic and foreign sales agents.Our company not only has formed a mature sales network in China, but also signed sales agency contracts with copanies from more than 30 foreign countries, and our machines has been exporting to Europe, Asia, Africa, South America, North America, Australia and other zones ,and have been trusted and praised by vast number of users. Our company focuses on strict and effective management,system, strict audit machines' quality ,try not to let out a detail, and make the machines more refined and finer .Service is our eternal theme of the pursuit. Our company can also procide OEM and ODM service .Is always adhering to the "QUALITY IS THE FIRST" purposes, to provide better quality machines ,more efficient and thoughtful after-sale service to customers . With your support, we will make great progress. Let's join hands and create a better future! Welcome to visit us!

8. FAQ

Q: Are you trading company or manufacture? A: We are factory. Q: How long is your delivery time? A: Generally it is 10~20 days if the goods are in stock.Or it is 30~60 days if the goods aer not in stock,according to your quantity. Q: Do you provide samples?is it free or extra? A: Yes,we could offer the sample,but need extra cost. Q: What is your terms or payment? A: 30% T/T in advance,balance before shippment.