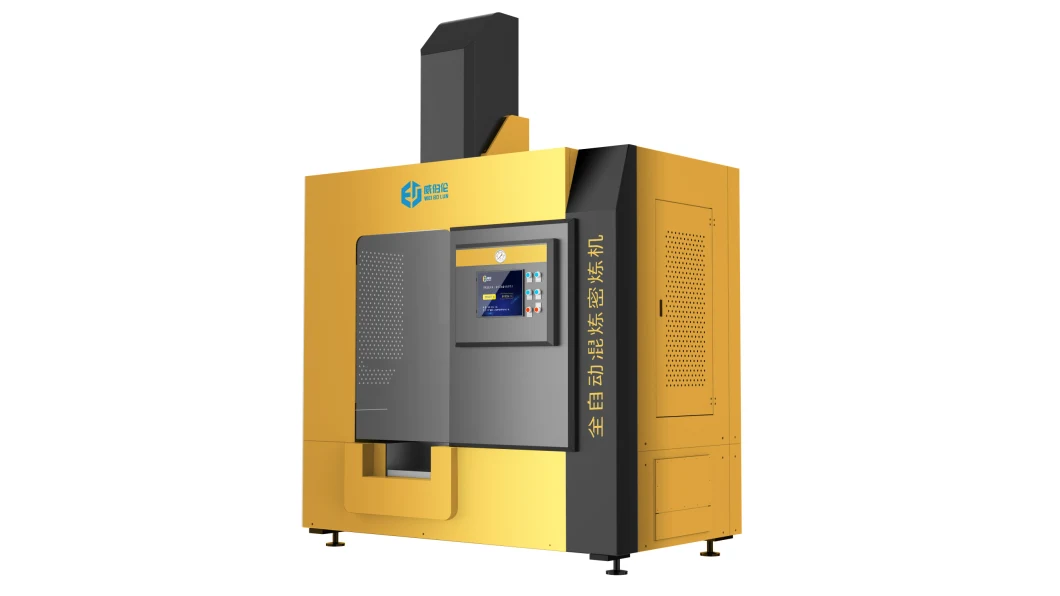

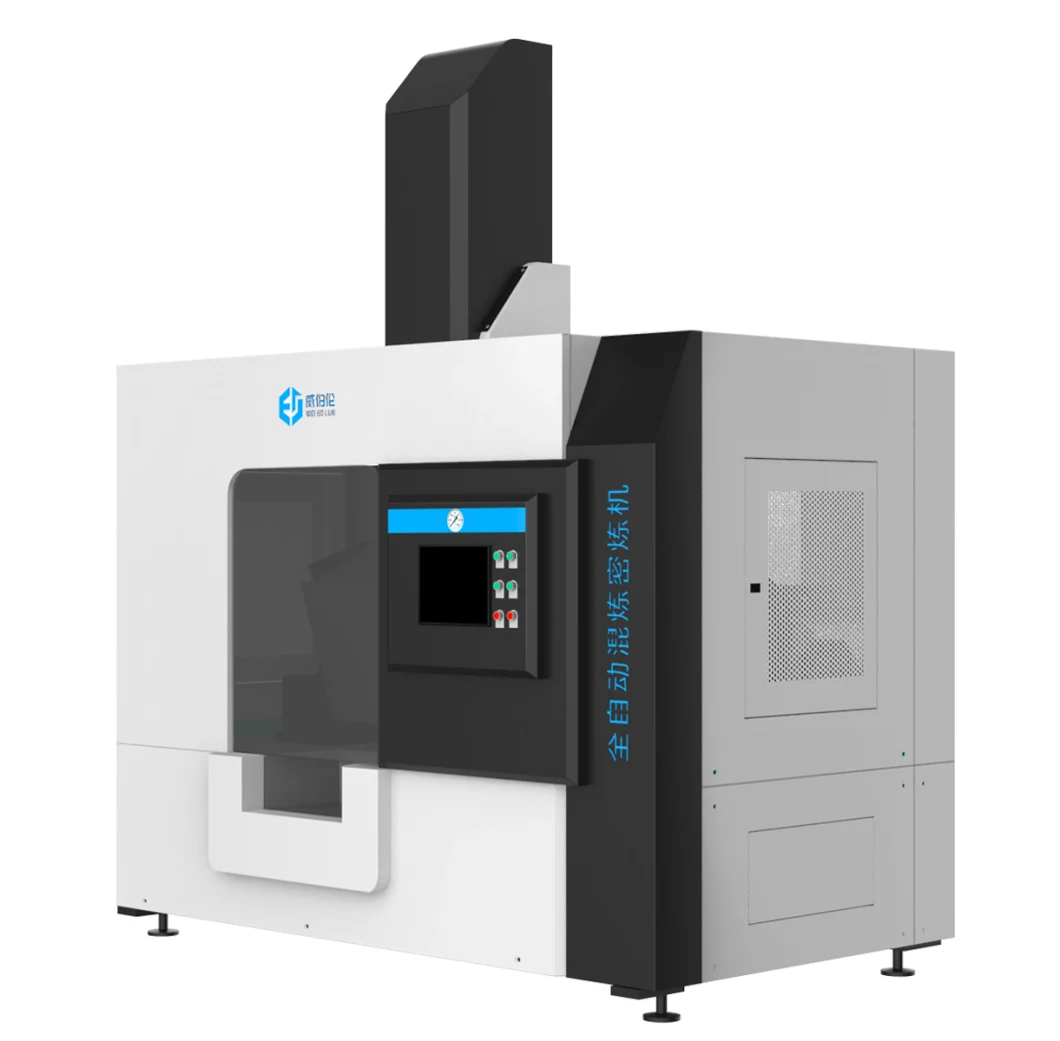

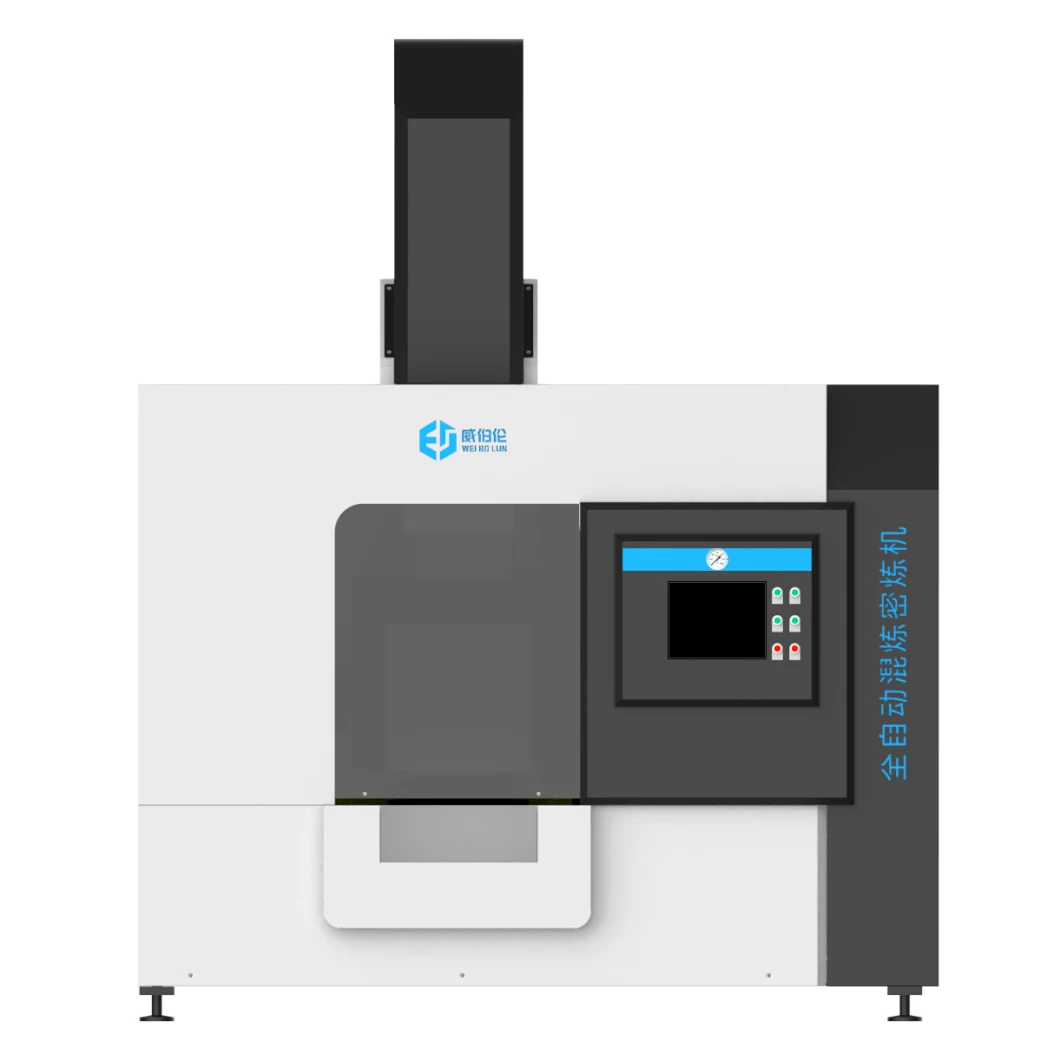

Professional Dispersion Stainless Steel Powder Mixing Metal Internal Mixer

Basic Info

| Model NO. | 10L |

| Specification | customized |

| Origin | China |

| Production Capacity | 500PCS/Month |

Product Description

Professional Dispersion Stainless Steel Powder Mixing Metal Internal MixerProduct Parameters

| Name | Metal internal mixer |

| Capacity | 10L |

| Drive motor | 15 KW |

| Rotation motor | 0.75W |

| Rolling angle | 110 |

| Production capacity | 45KG (per batch) |

| Weight | 2300KG |

| Size | 2200mm*1350mm*2150mm |

Weiberlun specializes in producing 10L metal mixer and 10L metal powder mixer. The 10L metal mixer is dedicated to the mixing of various metal powders in the MIM process, including stainless steel powder mixing, iron powder mixing, titanium alloy mixing, tungsten alloy mixing, copper alloy mixing, and so on. The 10L metal mixer can mix 45 kilograms at a time, with excellent dispersion effect and low maintenance rate, which has won the favor of MIM customers.

Working principle

When the 10L metal mixer is working, the two rotors rotate relative to each other, clamping the metal powder and adhesive from the feeding port into the roller gap, which is squeezed and sheared by the rotor. After passing through the roller gap, it touches the lower top bolt sharp edge and is divided into two parts, which are then returned to the top of the roller gap along the gap between the front and rear chamber walls and the rotor. During the flow around the rotor, the metal powder and adhesive are subjected to shear and friction effects everywhere, causing a sharp increase in the temperature of the metal powder, a decrease in viscosity, and an increase in the wettability of the metal powder on the surface of the adhesive, allowing the metal powder to fully contact the surface of the adhesive. The binder clumps, along with the metal powder, pass through the gaps between the rotor and the rotor, between the rotor and the upper and lower top bolts, and between the inner walls of the mixing chamber. They are sheared and broken, surrounded by stretched rubber and stabilized in a broken state. At the same time, the convex ribs on the rotor cause the metal powder to move along the axial direction of the rotor, playing a stirring and mixing role, making the binder evenly mixed in the metal powder. The adhesive is sheared and broken repeatedly, and the metal powder is deformed and recovered repeatedly. The continuous stirring of the rotor ridge makes the adhesive disperse evenly in the metal powder and reach a certain Dispersity.

Operation method

1. Calculate the amount of material to be mixed and the actual formula based on the capacity of the internal mixing chamber and the appropriate filling coefficient (0.6-0.7);

2. According to the actual formula, accurately weigh the amount of various raw materials in the formula, place metal powder and small materials (POM, PP, PE and other binders) separately, and arrange them in order on the shelf;

3. Turn on the power and heating switches of the mixer, preheat the mixer, and check whether the air pressure, water pressure, and voltage meet the process requirements. Check whether the temperature measurement system, timing device, and power system indicate and record properly;

4. After preheating the mixer, stabilize it for a period of time and prepare for mixing;

5. Lift the top bolt, put the metal powder into the mixer from the feeding port, drop the top bolt, and mix for 1 minute;

6. Lift the top bolt, add small materials, and drop the top bolt for mixing for 1.5 minutes;

7. Lift the top bolt, add POM/PP, and drop the top bolt for mixing for 3 minutes;

8. Lift the top bolt, add liquid softener, and drop the top bolt to mix for 1.5 minutes;

The mixing process test report for each batch of internal mixer should record: temperature at the beginning of mixing, mixing time, rotor speed, top bolt pressure, discharge temperature, power consumption, difference between the quality of mixed rubber and the total quality of raw materials, and the type of internal mixer.

Attention: When starting the mixing experiment, you can first mix a rubber material with the same formula as the experimental rubber material and adjust the working state of the mixer before formal mixing; For the same batch of mixed rubber materials, the control conditions and mixing time of the internal mixer should be kept the same. Company Profile

Xiamen Webron is a national high-tech enterprise, a star enterprise in Fujian Province, and a well-known innovative technology research and development enterprise. It was registered in the Cross-Strait Equity Trading Center in 2021, with the enterprise code of 867467; The headquarters is located in the Tsinghua Strait Research Institute. It is a 3A credit enterprise in China, a member unit of the Mechanical Mold Branch of the China Rubber Industry Association, a key recommended private enterprise in Fujian Province, and a member unit of the Fujian Plastic Industry Association; Signed contracts with 15 professors in the fields of polymer, metal, and ceramics, has industry-university-research cooperation with multiple universities, and has joint laboratories with universities; It is a metal ceramic rubber plastic machinery technology enterprise specializing in research and development, design, manufacturing and sales, and after-sales maintenance services. Company Vision: Let China's mixing technology synchronize with the world. Serving new material enterprises such as polymer materials, graphene materials, advanced ceramics, and powder metallurgy, our core products include torque rheometers, rubber internal mixers, metal internal mixers, ceramic internal mixers, internal mixing and granulation integrated machines, open mills, twin screw extruders, and plate vulcanizers.

The company has successively passed the certification of ISO 9001, intellectual property management system, and high-tech products. It has strong production capacity and advanced technological processing equipment, such as 10 five-axis CNC machining centers, 4 CNC lathes, 5 slow moving wire and other imported processing equipment. The company has independent laboratories, and various materials and experimental equipment are provided to customers for visiting/testing formulas/proofing. The professional R&D and design team can meet the special non-standard requirements of customers and customize the model, which has been recognized and praised by the majority of customers.

Since its establishment, Webron has worked hard, innovated, and made progress. The company promises to produce high-quality products for you with specialized technology, and to create higher value for you with high-tech achievements! Xiamen Webron Technology is willing to work with you to create a brilliant future!

Q1. How to choose the most suitable Mechanical Equipment ?

A1:Our professional team will give you the best suggestion as long as you tell us what kind of test you need to do andthe required specification.

Q2. What's the delivery term?

A2:At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15~20 working days after deposit receipt. If you are in urgent need, we can consider making special arrangement for you.

Q3. Do you accept customization service?

A3:Yes, of course, we can not only offer standard machines, but also customized machines

according to your request. Don't hesitate to tell us your requirement, we will try our best to meet your needs.

Q4. Can we visit your factory before order?

A4:Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to arrange hotel and pick up you from airport.

Q5. How about your warranty?

A5:1. Provide on-site installation guidance;

2. Responsible for on-site commissioning and trial run of the supplied equipment until it passes the acceptance;

3. Responsible for on-site operation and maintenance training for Party A's personnel;

4. The unit is warranted free of charge for one year under correct use, and the supply of spare parts is guaranteed for a long time;

5. Provide long-term free technical service consultation;

6. Within and outside the warranty period, the supplier shall provide clear solutions within 3 hours after receiving the buyer's equipment failure notification