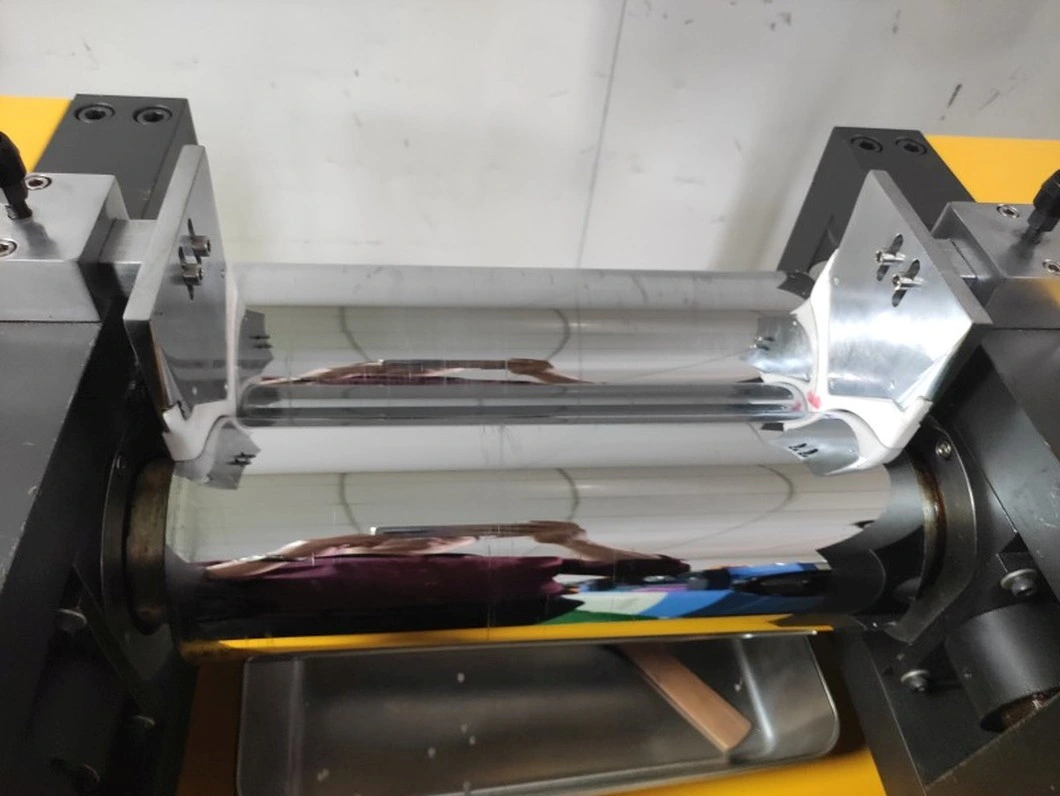

Lab Two Roll Mill with Oil Heating Twin Roll Mill

Package size per unit product 1350.00cm * 65.00cm * 1350.00cm Gross weight per unit product 650.000kg Product Descriptio

Basic Info

| Automatic Grade | Semi-Automatic |

| Power Source | Mechanical |

| Type | Open Mixing Mill |

| Transport Package | Wooden Case |

| Specification | L1350*W650*H1350 |

| Trademark | nordass |

| Origin | China |

| HS Code | 8441309000 |

| Production Capacity | 100PCS/Year |

Packaging & Delivery

Package size per unit product 1350.00cm * 65.00cm * 1350.00cm Gross weight per unit product 650.000kgProduct Description

Product Description

Machine Introduction

Lab two roll mill is widely used in rubber, plastics industries. Such as polyolefin, PVC, film, coil, profile production and polymer blending, pigments, masterbatch, stabilizers, stabilizers and so on. The main purpose is to test raw materials's physical properties change and contrast after mixing. Such as color dispersion, light transmission, substance table.

Machine Specification

| MODEL NO. | BDS-LAK60 |

| EXTERNAL SIZE | L1350*W650*H1350 |

| POWER | 380V/11KW |

| AIR PRESSURE | NA |

| WEIGHT | 750Kg |

| SPEED | 0~30r/min |

| MIXED MATERIAL VOLUME | 500g~2kg |

| ROLLER SIZE | ф200mm×L400mm |

| ROLLERS GAP | 0.1-10mm Adjust |

| ROLLER RATIO | Frequency Control Of Motor Speed |

| ROLLER CONTROL TEMPERATURE | NP~300ºC |

| TEMPERATURE ACCURACY | +/-2°C |

| COOLING METHOD | Water Cool Down Independ Or Oil HEAT&Cool |

Company Introduction

Dongguan bodas Intelligent Technology is located in the famous manufacturing city of Dongguan, Guangdong. It is a manufacturer of rubber and plastic experimental equipment, post printing packaging equipment and testing equipment integrating R & D, production and sales. The company was established in 2006 and is committed to the development of reliable, easy-to-use equipment to improve the manufacturing quality of products and reduce costs. At present, the company has 6 engineers, 23 processing and assembly technicians, and 4 pre-sales and after-sales personnel. After the integration in 2021, the company's business has been steadily improved and can provide customers with more personalized and efficient equipment. At present, the company covers an area of 1800 square meters. There are 3 CNC machining centers, 8 milling machines, 2 ordinary lathes, 1 surface grinder, 1 large water mill, 1 tapping machine and a cutting machine.

Shipping And Packaging

| Shipping | By sea, or as your requirement to do | |

| Packaging | By Strong Wooden Case | |

FAQ

Q: How to find the machine suitable for my product?

A: Tell us about your product details and packing requirements. 1. What kind of product you would like to treat? 2. The bag/sachet/pouch size of you need for the product packing ( the length, width). 3. The weigh of each pack you need. 4. You requirement for the machines and the bag styleQ: Is engineer available to serve oversea?

A: Yes, but the travel fee is responsible by you. In order to save your cost, we will send you a video of full details machine installation and assist you till the end

Q: How can we make sure about the machine quality after placking the order?

A: Before delivery, we will send you the pictures and videos for you to check the machine quality. And also you can arrange for quality checking by yourself or by your contacts in China

Q: What time for delivery ?

A: Machine about 45days after get your down payment , paper cone as the quantity

Q: Can you explain me the whole transaction process ?

A: 1.Sign the Contact 2.Arrange 50% deposit to our factory 3.Factory arrange production 4.Testing & detecting the machine before shipping 5.Inspected by customer or third agency through online or site test. 6.Arrange the balance payment before shipment

Q: Will you provides the delivery service?

A: Yes. Please inform us of your final destination, we will check with our shipping agent to quote the shipping cost for your reference before delivery.

Send to us