1-20L Rubber Dispersion Kneader Mixer Machine, Rubber Internal Mixing Banbury Machine

Product Description: This machine is suitable for stiring, kneading and dispersion of all kinds of chemical raw material

Basic Info

| Model NO. | XH-420 |

| Control Mode | Key Control/PLC Control (Optional) |

| Drive Model | 11kw |

| Flip Motor | 0.75kw |

| Rotor Speed(Front and Rear) | 40r/30min (Speed Adjustable) |

| Flip Angle | 110ºC |

| Air Pressure | 0.3-0.5MPa |

| Volume(H*W*D) | 1900*1300*1500mm |

| Weight | 1500kgs |

| Power Supply | 3∮, AC380V |

| Transport Package | Wooden Case |

| Trademark | Xihua |

| Origin | China |

Product Description

Product Description:This machine is suitable for stiring, kneading and dispersion of all kinds of chemical raw materials, such as plastic, rubber, synthetic rubber hot melt adhesive, etc. And then put the formula into the production line. This machine is equipped with PLC man-machine interface, temperature control module, and heat condition oil heating cooling system. Make it easy to operate, fast heating and cooling. With this machine, you can do many different experiments of all kinds of material in a short time.

| XH-420-1L Technical parameter | |

| Mixing Volume | 1L, 3L, 5L, 10L,25L |

| Control Mode | Key control/PLC control (optional) |

| Flip Motor | 0.75kw |

| Rotor speed (front and rear) | 40r/30 min (speed adjustable) |

| Filp Angle | 110ºC |

| Air pressure | 0.3-0.5Mpa |

| Volume(H*W*D) | 1900*1300*1500mm |

| Weight | 1300kgs |

| Power supply | 3∮, AC380V (or customized) |

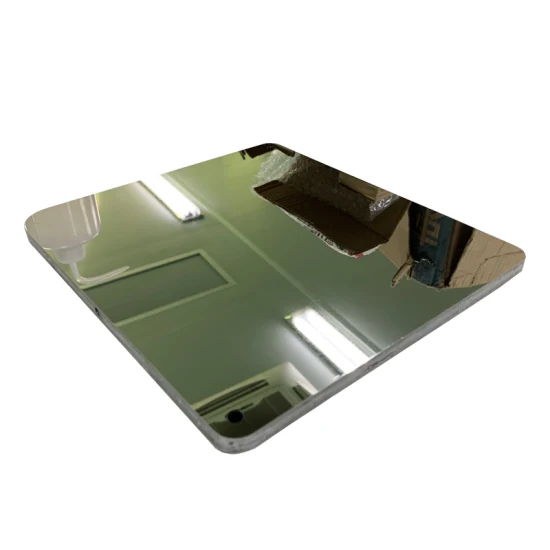

Details Images

Internal Mixer Features

1) The local device automatic temperature and time control system, precise operation, simple and easy, mixing up and take the best uniform dispersion effect2) The mixing tank to be dumped style, mixing shaft mechanical seal leak dry cleaning so easy to change colors easily3) Pressurized sealed mixing chamber to ensure the quality of the mixture outside and prevent environmental pollution4) Mixing tank using advanced alloy steel, wear-resistant steel surfaces are treated by surface abrasion particularly good, hard chrome plating5) Electronic control requires adjustments according to customer requirementsOther size of Lab kneader. Such as 1L,3L,5L,10L,25L

Our Service

If you face any problems in future during testing process we promise we will give you a reply within 24 hours and solution provide within 2 working days. We can offer operation video and English operation muanual. We can provide operation video for machines.Onsite Service

A. Device installation;

B. Equipment Operation Test Technology training;

C. Equipment Calibration;

D. Daily maintenance and maintenance of equipment

Free technical training for visiting factories

24-hour Online contact

Free software upgrades

Free information

A.Product Instruction;

B.Product operation instructionvideo;

C.Experiment Test (test application, test report)

24-hour Online contact

Free software upgrades

Free information

A.Product Instruction;

B.Product operation instructionvideo;

C.Experiment Test (test application, test report)

Device Problem Handling

A. Social media 24 hours online communication;

B. Mail Seamless Docking;

C. Video Conferencing;

D. Artificial free door-to-door service

Send to us